Meta description: A lot of equipment requires extra protection from environmental influences. Fields like medicine, building and construction, transport, and communication use tools that should be protected. Compounds like epoxy resins and polyurethane potting compounds allow you to shield your tools through potting resins. Would you like to know which areas epoxy potting materials are commonly used? What is the epoxy resin product best for each area of application? What are the characteristics of each product? You are reading a perfect guide if you have such queries. This manual covers the following:

Epoxy potting in Electronics

Epoxy potting for LEDs

Cable and Plug Potting

Epoxy Potting in Optics

Epoxy potting in building and construction

Epoxy Potting for Marine Technology

Epoxy Potting for IP Protection

Epoxy Potting in Oil and gas Sensors

Epoxy Potting in Aerospace

Epoxy Resin in Turbine Technology

Potting refers to shielding a device’s sensitive parts using specific potting compounds like epoxy resin. This potting protects from vibration, electrical shock, chemical and water damage.

1. Epoxy Potting in Electronics

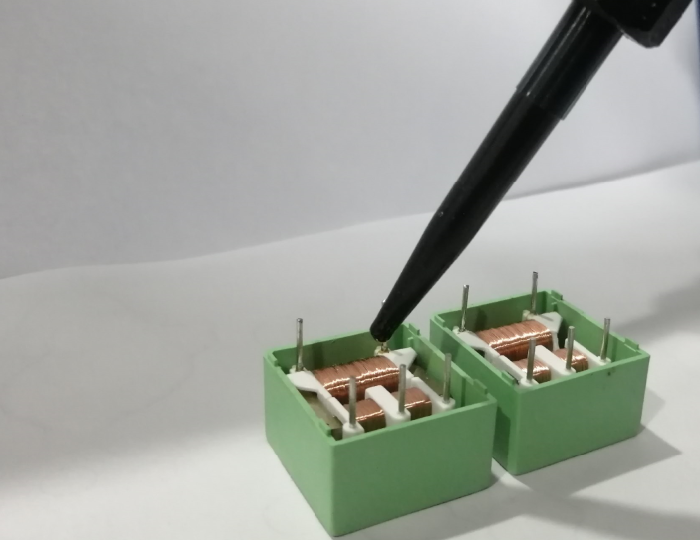

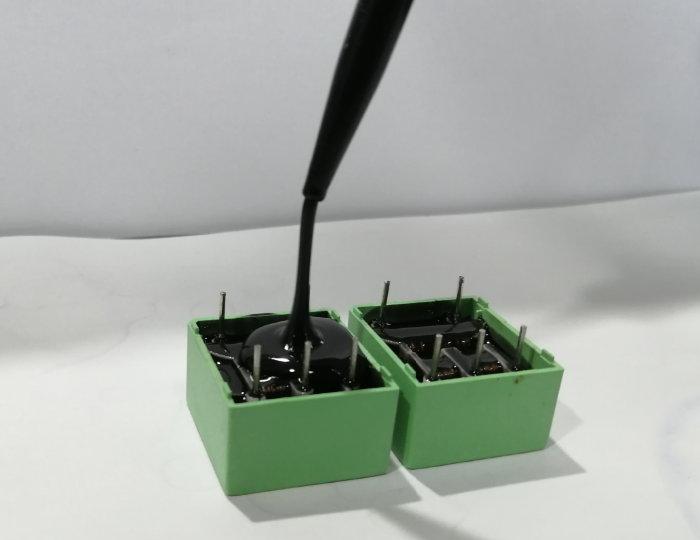

Potting electronics like PCB, coils, transformers, chargers and motors protect electrical components from moisture, chemical corrosion, vibration etc. To pot an assembly like PCB, you need to put the assembly in a special potting box and then pour the potting compound carefully. After the resin completely cures, it forms a layer that provides good electrical insulation.

If you want to pot your electronic assembly like PCB, follow these simple steps:

Select the right potting resin for your project. Consider factors like cost, adhesiveness and the desired features of your product, like final hardness. Epoxy resin is ideal for potting.

Measure and Mix the resin and hardener per the ratio given by the manufacturer

Prepare the application surface. In this case, ensure that the PCB surface is clean and fixed in the potting box.

Pure the epoxy compound carefully onto the surface and allow it to cure

Curing makes it hard and hence provides protection. suitable

Best Epoxy Resin for PCB Potting

The best brand for PCB potting is HENKEL. It comes with the following features:

Has insulating properties

High strength

Chemical resistance

Not affected by humidity changes

We have equivalent potting epoxy brands at resinoo. You can visit us to access a variety of products. It can be used for general purposes. The brand has the following characteristics:

A mix ratio of 2:1

Glossy finish

Ability to stand shock

Electrical insulating properties

Chemical resistance

The diagram below shows the epoxy resin mixture poured into an electronic component during the potting process.

2. LED Potting

Sensitive parts of light-emitting diodes need to be protected. The components should be shielded from dust, water and other environmental factors like a shock. Thanks to epoxy resins’ transparency feature. It is ideal for LED potting. Epoxy resins from resinoo are ideal for LEDs. They:

Shield the LED from mechanical and thermal shock

Protect the sensitive parts from moisture and hazardous chemicals

Protects LED from harmful UV rays

Led Potting Procedure

Measure and Mix the epoxy resin and hardener in the ratio given by the manufacturer

Put the LED in the potting box like the one below:

Pour the mixed resin and hardener onto the LED carefully.

Allow it to harden (cure) at glass transition temperature

3. Cable and Plug Potting

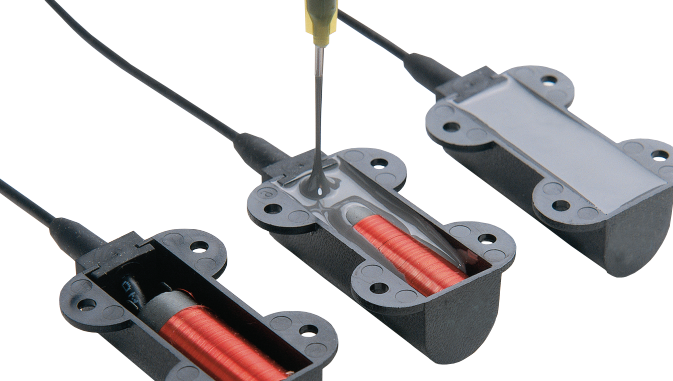

Electrical cables are potted to shield them from mechanical damage and other environmental risks. When a cable is fitted in a plug, spaces that need to be filled may be left. The diagram below is an example of a plug and cables which require epoxy resin potting.

The Procedure for Cable and Plug Potting

For cable and plug potting, follow the easy steps below:

Fit all the contacts properly

Mix the potting resin and hardener as per the instructions given by the manufacturer

Ensure that the ambient temperature is optimum for proper curing process

Fill a syringe with the compound as shown below:

Fill the spaces with the epoxy resin as shown below and wait for it to cure

Once it is fully cured, the project is complete.

Resinoo epoxy brand has all the features you desire for cable and plug potting. Some of the unique attributes of resinoo are:

Short curing time

Will attain the required hardness after cure

Resinoo brand is affordable

It can be used in a wide range of temperature

4. Epoxy Potting in Optics

Optical devices require extra protection through potting. To select the best potting material for your optics, consider the following:

The curing time

Viscosity

Ambient temperatures for the cure

The desired hardness

Resinoo epoxy resin is ideal for optical assembly. It has:

Low viscosity, hence can be used for thick layers

Highly flexible

Has excellent optical clarity

Lower working life

Less exothermic

The Procedure for Potting Optical Devices-Goggles

Select the epoxy resin brand that will best serve your project

Take the specific mold that you will use

Pour the resin mixture gently

Once it cures, the product takes the shape of the mold.

You can now separate the resin and the mold.

The epoxy resin should not adhere to the mold in this case.

5. Epoxy Potting in Building and Construction

Potting epoxies are widely used in building and construction. Some of the common uses of constriction include:

Laminating desks

Door coating with glossy finish

Concrete floor sealers

Adhesives for coating floors

- Wall stickers doming potting

Moreover, epoxy resin is used in water-based manufacturing paints, which are used in construction. Where good thermal conductivity is required, ensure that epoxy resins are not put between two conductors.

Example: Epoxy Flooring Procedure

To successfully apply epoxy on the floor, follow the simple steps below:

Prepare the flow for the application. Ensure that you remove any dirt from the surface. Any dirt, like dust, can contaminate the epoxy.

Level the surface. For the application layer to be even, you must ensure that the surface is flat.

Pour the epoxy on the surface and spread it evenly

Leave the epoxy to cure. Curing hardens the surface

Apply a top coat to make the surface more attractive and shiny.

There are many epoxy resin brands for flooring. To choose the best, consider the following:

Areas of application. Some epoxy brands can be applied in many areas

The ease of application. Some brands like Epoxy Resin 2 Gallon Kit Industrial Grade can be applied easily

The desired hardness of the finished product

Water and chemical resistance

6. Epoxy Potting in Aerospace

Speed sensors in airplanes are potted using epoxy resins. The resins have high-temperature stability of above a hundred degrees Celsius. Epoxy resins are used for different bonding components in an airplane. Epoxy layers are sandwiched between fiberglass cloth for protection in a spacecraft. The lightweight feature of epoxy resin makes it ideal for aerospace applications.

Light-weighting increases flexibility and reduces fuel costs. For exterior surfaces, epoxy can also be used.

Epoxy resins are ideal for potting any airplane part. They can adhere to a variety of materials hence making them widely useful. The casing of an airplane can be coated using epoxy resin. Here, the resin is applied via spraying. You only need to mix the resin and hardener and pour them into the spraying machine.

7. Epoxy Potting for Marine Technology

Epoxy resin is the ideal potting compound for underwater tools. To pot a piece of underwater equipment using epoxy, follow the steps below:

Choose the best epoxy brand for your project.

Mix the resin and hardener as per the ratio given by the manufacturer

Prepare the surface for application

Pour the resin compound gently and leave it to cure

Epoxy potting is commonly applied in joints of high-voltage carrying cables. Since epoxy is strong and insulating, it is ideal for such joints. Epoxy resin is also used for underwater sensors.

The procedure of potting any underwater device is similar to the one for tools used on dry land. At resinoo, we have different products for you.

8. Epoxy Potting for IP Protection

You can protect your Intellectual property using Epoxy resins. How can you achieve such protection? The procedure is straightforward. Since epoxies are hard to remove once fully cured, you only need to use them in potting your product. Epoxies are chemical resistant hence not easily destroyed.

Example: For power suppliers, a manufacturer can have a unique design. Maybe, the design makes their products unique. For competitive advantage, they can pot their product to keep it a secret from competitors.

9. Epoxy Potting in Oil and Gas Drillers

Epoxy resins are used in oil and gas drillers. Since they have strong adhesive properties, they are ideal to work under high pressures. Some epoxy brands can withstand temperature changes. Sensors used drilling technology are potted using epoxy resin. The epoxy compound protects them from any mechanical damages and environmental influences like shock and chemicals. At resinoo we have a wide range of products for you.

10. Epoxy Resin in Turbine Technology

Last but not least, epoxy resins can be used in Turbine technology. Resinoo has a variety of products that can meet the pressure of wind blades. Epoxies are used in a wide variety of oil and gas equipment. Epoxies have a wide variety of applications, including sealants, adhesives, encapsulating, and coatings. Epoxies have physical and electrical Insulating qualities, Epoxy resins exhibit temperature and chemical resistance, dependability, and simple application procedure. Chemical resistance makes epoxies ideal for areas of high thermal conductivity like oil and gas industry.

Final Remarks

At resinoo, we have all what you need. Just visit our website and share the story. Our epoxy experts are ready to give you solutions to your questions.

- Melap Portugal — guia de casinos online licenciados e também sites para apostas dentro de território português

- International Dating Challenges: How to SolveThem

- Znaki Sverige: nyheter om de verksamheter som påverkar den moderna världsbilden

- Best Pills for Erection: Your Comprehensive Guide to Enhanced Performance

- TOP 6 Epoxy Resin Applications in 3C Electronics Industry