Are you a fan of arts and crafts? Or maybe just into the handy tasks? Then chances are that you have come across a clear, transparent liquid known as epoxy resin in the works.

Here is how we know it. Epoxy resin is a synthetic polymer product with high heat resistance mixed and used in large quantities. It is used across different disciplines and is versatile, heat resistant, and efficient in cutting across many fields.

What is Epoxy Resin, and How does it Work?

Epoxy resin has many uses in different disciplines, including arts, and crafts, composite materials, and material sciences.

While we might have heard of epoxy resin from time to time, it is possible to not fully understand what brings about this substance, how it works, its applications, and its uses. At Resinoo, we ensure access to the most suitable epoxy resin products for your application, ensuring that your application is easy to use.

We Are The Epoxy Resin Service Professionals, and in the rest of this article, we will be taking you through a guide on just what crystal clear epoxy resin is. Here, we will cover how it is made, how it works, and its pros and cons in the application.

That being said, let’s get right into everything you need to know about epoxy resin.

What is resin?

Resin is a non-crystalline or viscous substance that can be synthetic or organic from a reactive functional group. Other resins include amino resins as well.

While we have natural resins, many of them have been replaced in the industry by synthetic epoxy resins, which might have a few of the same physical properties but differ chemically.

The synthetic epoxy resin is created from a combination. These synthetic resins can be divided into two major classes

Thermosetting – which becomes insoluble

Thermoplastic – which remains plastic on heating

Epoxy Resins: A synthetic Resin with many applications

Epoxy resin is a specific type of synthetic resin. It falls directly into the thermosetting class as it is made from monomers with at least two epoxide groups. The epoxy resin then forms thermosetting polymers.

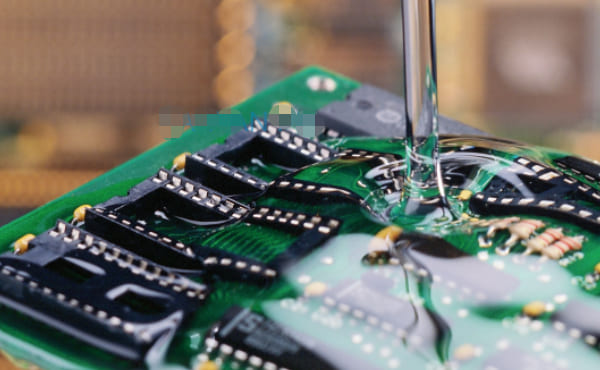

The resin reacts primarily with the catalyzed compounds or with multiple reactions, e.g., amines, phenols, thiole, and others. Epoxy resins are often applied for various uses in the manufacturing industry.

What are Epoxy Resins used for?

We commonly use Epoxy resin for building vehicles, snowmobile aircraft, and cycling equipment. Epoxy Adhesion is also available for structural applications. In fact, it’s possible to use these tools anywhere. We typically employ epoxy because of its wide variety of applications for different applications.

Use and Applications of Epoxy Resin

The uses and applications of epoxy resin vary across fields and disciplines based on their uses. However, some of the generic uses of epoxy resins include use as;

strong adhesives

casting and hardener for materials

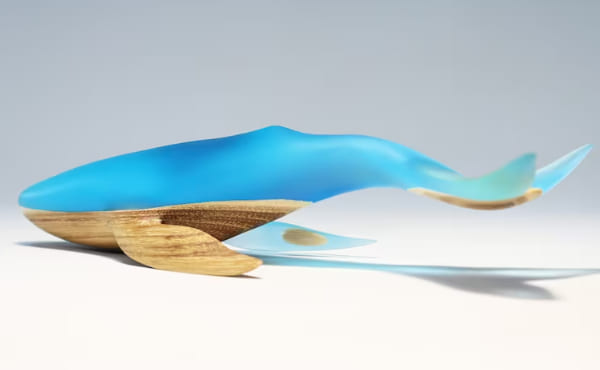

creation of decorative objects

Paint and Coatings

glass and structural sealants

Gelcoats

Jewelry and artwork

Some of the uses of epoxy resins are concerning the industry or field in which they are utilized.

As you might have guessed, we widely utilize Epoxy resin across aerospace, food processing, automotive, sports, construction, and renewable energy fields thanks to its chemical properties and molecular weight.

Industries that utilize high-quality epoxy resin

As previously stated, the application and use of epoxy resin across industries vary. We would be looking at different industries that deal with this substance, how it is used, and its importance to their operations.

Building and Construction

When we talk about the relationship between the establishment of structures and clear epoxy resin, one key thing to note is that epoxy resin improves specific structures’ durability and quality.

This means that it reduces the need for refurbishing and ongoing maintenance. Epoxy resin is a cost-effective and efficient material in building and construction. They are used in glass coatings, paint, hardware stores, DIY projects, and anti-corrosive primers.

Epoxy resins are also used in flooring applications, especially in facilities that require sterile surfaces. It is also largely utilized in plumbing and piping thanks to its resistance to chlorine and microbes and solid adhesives across most construction processes.

Aerospace

Epoxy resins are primarily used in the aerospace industry to reinforce materials like glass and carbon. It acts as an effective binder that makes them stronger and more durable, and a lightweight option.

When used as an adhesive and reinforcement of structural parts, epoxy resins give high strength to materials. They can also help these parts withstand the temperature imbalances and extreme weather conditions of operating aircraft.

Sports

Across most sports, three things are crucial. Moisture resistance, little to no abrasion, and durability. The last thing you want is cracked or broken equipment in the middle of a tournament.

Epoxy resins play a significant role where these three things are concerned in the sports industry. This polymeric mix is used to coat sports equipment, making them more durable and water-resistant and reducing their abrasion.

Under elevated temperature and lower viscosity, epoxy resin generally gives better mechanical properties, even under elevated temperatures. The chemical resistance and molecular weight make it a plus for athletes using high gloss epoxy resin-coated materials.

Examples of such applications include kayaks and tennis rackets.

Automotive

If you like a shine of a brand-new car, then you should know that high-quality epoxy resin is also at work here. Epoxy resins are used as a strong adhesive and rust and corrosion-resistant catalyst.

While a more used color is transparent crystal clear epoxy resin to light brown, it can also be mixed with other colors. Other industries include food processing, art, design, and decorative materials.

Thanks to its tensile strength and low shrinkage, it can also be used for marine applications like marine repair and boat repair.

Is there a difference between resin and epoxy?

Epoxy-coated resin has a greater viscosity stability than casting resin. It is mainly used in small manufacturing, such as the manufacturing of industrial prototypes and in the dental sector. It can be dried more rapidly than casting resins. Unlike cast resin, epoxy coating resin requires relatively short processing times. Since there are no mixed ink layers, the control of these layers is much easier.

The Chemistry Behind Epoxy Resin

How did crystal clear epoxy resin, the synthetic resin come about? The epoxy group from which epoxy resin comes is characterized by its reactivity towards both nucleophillic and electrophilic substances. As a result, epoxy resin is receptive to a wide range of curing agents. Such curing agents are of two types: they may be either catalysts or hardeners whose derivation can be traced to aromatic amines and fatty acids.

How to cure epoxy resins

High-quality crystal clear epoxy resin undergoes three processes where curing is concerned. These processes kick off with the mixing of epoxy hardener and epoxy resin.

The procedure of taking epoxy resin from liquid to solid epoxy resins involves three key stages

Open stage of curing epoxy resins

Here the epoxy resin is in a crystal clear epoxy resin liquid state. It can also be known as the mixing stage of epoxy esters, where crystal clear epoxy resin is mixed with a hardener. In this form, the epoxy resin is very workable.

It is easier to manipulate and shape into the desired form and onto the desired surface. This epoxy resin curing process is the first stage. Partial curing takes place.

Solid Epoxy Resin Stage

This stage comes after mixing and manipulating all the resins and hardeners to get the desired casting molds. At this point, the epoxy resin is not workable anymore and has undergone a consistency change. It will have the strength and hardness of rubber at this stage.

Cured stage

This is the end stage of the epoxy systems mixing process. You can no longer make a dent at this stage as it has now hardened and taken shape. Here you can remove the clamps. The epoxy resins here will have attained thermal conductivity and chemical resistance.

High-Quality Epoxy Resin Curing time

Most resins, especially the ones used for broad range floors, are accessible for light use from the second to third day. Fast-cure resins boil down to two components or co-reactants of importance. The hardener used and the type of resin used makes it perfect for your DIY projects.

On a general note, epoxy resins take around 7 days after the coatings for the completion of the three stages. Although this may vary between applications and uses. Other factors that affect curing time include

Elevated temperature,

Low viscosity (The lower the viscosity levels

Type of hardener used

How long epoxy resin lasts?

Epoxy shelf life may be extended by putting resin and hardener in an enclosed container to protect against contamination. For those using polyester, the shelf life is six months before it turns into jelly-like material. However, it all comes down to the quality of the epoxy resin used in the production process.

Get Exceedingly Good Epoxy Resin From The Factory with Resinoo

Our experienced team of experts quickly provides the most suitable epoxy resin products for your application, ensuring that your application is easy to use. At Resinoo, we ensure that your product results are of the highest quality and that your business grows steadily.

We Guarantee Your Constant Results Of Epoxy Resin. We Are The Epoxy Resin manufacture&Service Professionals!

- Znaki Sverige: nyheter om de verksamheter som påverkar den moderna världsbilden

- Best Pills for Erection: Your Comprehensive Guide to Enhanced Performance

- TOP 6 Epoxy Resin Applications in 3C Electronics Industry

- The Role of Epoxy Resin in Enhancing Electronics: Applications and Benefits

- A Comprehensive Guide to Epoxy Potting in Industrial Applications