If you have ever been to a repair garage or you love DIY crafts then I bet you have ever heard of or used epoxy products. Epoxy resin refers to a reactive class of polymers containing epoxide groups. When reacted with hardeners, epoxy becomes hard and is used in almost every industry. At room temperature, epoxy resins are solid. They can get to their viscous state when exposed to heat. Apart from being used in paint, our epoxy resins have a wide range of use. You can never miss them in areas like building and construction, food industries, etc.

What Is Epoxy Resin Made Out Of

Our standard resin kit consists of two components i.e resin and a hardening agent. Epoxy has four main components;

Monomeric resin

Hardener

Accelerator

Plasticizer.

We manufacture resins by combining epichlorohydrin (ECH) and bisphenol-A (BPA). ECH is a colorless chlorinated epoxy compound that has a pungent odor. BPA is a crystalline compound used in the production of plastics and resins. We can replace BPA with other raw materials to produce different epoxy variations.

Production Process

To produce epoxy, we charge ECH and BPA into a reactor. We then heat the solution to its boiling point. Unreacted ECH is separated by adding an inert insolvent. Resin proceeds to the washing process. The solvent is removed by vacuum distillation. We use specific additives to achieve required properties like flexibility. Raw resin does not have the required properties i.e chemical heat resistance and there is a need to harden it. We cure the resin with a hardener at a temperature of 5-150 degrees. Temperatures depend on the curing agent used. There are a variety of hardeners i.e amines, and acid anhydrides.

Epoxy Additives

Epoxy is compatible with other components and we customize it to suit the intended use. For example, we use thickeners to make it thicker and avoid running and sagging. Here are the most common additives we use:

Powdered metals: Metal powder such as Mica or Alumina powder is added to the resin. This alters its thermal and electrical conductivity. We can also mix with other metal powders; the end product is used to make a metal finish.

Rubber: To increase the flexibility and toughness, we add Liquid rubber.

Flame retardants: Epoxy resin can catch flame with ease. We add flame retardants to reduce their flammability.

Coloring agents: To achieve the desired color, we use alcohol and resin dye.

Curing Process

Curing is the process by which epoxy transforms from liquid to solid. Cure time is the time it takes to completely transform. To speed up the curing time, we add carboxylic acids. We also use alcohol in small quantities. As it cures there is an exothermic reaction as the resin passes through 3 states:

Liquid state: This is the stage where epoxy is liquid and workable.

Gel state: At this stage, epoxy is no longer workable and its firmness can be almost the same as that of rubber.

Solid state: This is the final state where epoxy has completed its chemical reaction and is now hard.

Properties Of Epoxy Resin

When cured, our epoxy products have characteristics like:

Low shrinkage

Heat resistance

Corrosion resistance

High chemical resistance

Super adhesion to a wide range of substrates

Types Of Epoxy Resin

There are a lot of variations of epoxies but here is a list of what we manufacture.

Novolac Epoxy Resins

We make this variation by reacting phenol and methanol. The finished product includes a material that performs in heat and chemical resistance. Novolac resins can be used in high-temperature applications that need extreme chemical resistance.

Aliphatic Epoxy Resins

We produce this type by the epoxidation of double bonds. Cycloaliphatic epoxides may be used to encapsulate electronic systems like LEDs.

Bisphenol Epoxy Resins

For this variation, we mix BPA and ECH with a catalyst. This type is one of our most used epoxy resins. We may also use Bisphenol-F to make resins with lower viscosity and a higher mean epoxy content per gram.

Glycidyl Amine

For this type, we react aromatic amines with ECH. This makes resins with high thermal stability and good adhesion. With its properties, glycidyl amine can be used in the aerospace and plane industries.

Common Uses Of Epoxy Resin

Adhesives

Unlike other adhesives, our epoxies have high heat and chemical resistance. This makes them suitable for high-performance adhesives. These adhesives can also be used in ship construction, aerospace, and automobiles.

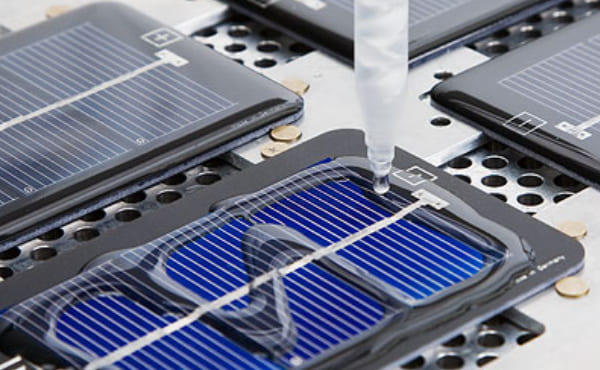

Electronics

Epoxy resin has its major primary usage in the electronics sector. It forms a perfect insulator that protects components from short-circuiting. Epoxy resins are used in electrical components like generators, motors, and printed wiring boards. In transformers, a resin dispensing system is used to fill, seal and cover technical parts.

Paintings

Epoxy paintings are greatly used in areas where corrosion is common. These are industries like automotive primers or marine. Food packaging containers are usually coated with epoxy to prevent rusting in cans. Epoxy resins have low UV resistance and much exposure to sunlight makes them yellow over time. In marine repair, a UV-resistant layer is applied on top of the epoxy to prevent yellowing.

Building And Construction

Our epoxy resins are used in coating environments that need sterile surfaces. These environments include food processing and medical facilities. You can clean floors that have an epoxy coating with strong cleaning products. Epoxies are also used in decorative flooring i.e a terrazzo floor used in countertops.

Industrial Tools

Epoxy systems are used to produce molds, laminates, fittings, and coating. Epoxies come in handy when producing fiber-reinforced replacing the use of wood.

Consumer Use

The adhesive properties of our epoxy resins make them suitable for consumer use. Epoxies are sold as a pack containing resin and hardener which is mixed only before use. Consumer use of epoxy resins includes DIY projects, art, and some minor repairs at home. Woodworkers make river tables using clear epoxy resin. A river table is made of two pieces of wood then they pour epoxy resin to fill the gap between the woods.

How To Apply Epoxy

To apply epoxy to a surface like floors we recommend cleaning the surface. You must ensure that the surface is dry completely before applying the epoxy. An overnight can do but it would be best to apply epoxy 24 hours after cleaning. You should set up your mixing area near the site where you want to apply epoxy. At least 2 people need to be on the site: one to mix and the other to do the application.

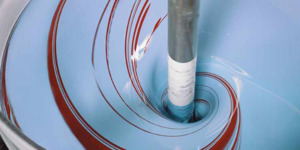

To avoid confusion, I prefer placing every epoxy resin near its hardener. First pour the resin into the mixing container, followed by the hardener then mix. Pour the mixture onto your surface then use a squeegee to spread it over till you get a thin and even layer. To ensure a smooth and more even finish you can use a roller to go over your layer.

If you want to add more layers of epoxy, leave the first coat to dry before applying the second coat. Before applying the second layer, ensure to sand. Sanding gives the second course to stick to the first firmly. Failure to sand might cause delamination.

Soft Or Bendy Resin

If you applied resin and after 24 hours it is still soft, it is most likely not cured well. You may have to give it some more time. If after a week and it is still bendy, high chances are that you never measured the correct amount of resin. You might also not have mixed the resin. We encourage our customers to read the instructions in all our products.

Top 4 Epoxy Manufacturers In The World

United Resin Corp– United Resin Corp manufactures epoxy for electronics and marine repairs.

Resinoo.com– Second on the list comes a global supplier of epoxy resins. In Resinoo, we provide epoxy resin, and polyurethane high-performance composite materials. Our products have high weather resistance and excellent heat insulation.

Copps Industries Inc– Copps Industries manufactures standard and custom carbon fiber, construction epoxies.

Key Resin Co.– Located in Batavia, Ohio, Key Resin is a bulk epoxy manufacturing company. It has produced clear epoxy resins used in coating table tops since 1993.

Frequently Asked Questions

Is epoxy resin glue?

Yes, you can use PU crystal glue BZ-5518-3 at home as an adhesive for repairs. It comes in handy in both indoor and outdoor repairs and forms a permanent bond. The BZ-5518-3 TDS resin glue takes more than 3 years without turning yellow.

Is epoxy resin waterproof?

Yes, when epoxy dries well, it hardens and forms a strong waterproof bond hence you can use it on leaking roofs.

What is clear epoxy resin used for?

You can use clear epoxy resin in covering paintings and encasing electronic products. Clear epoxy resin has good adhesion with wood woodworkers may use them in coating table tops

How long does it take for the epoxy to harden?

The curing time of epoxy has a lot of variations. Mixing ratio, the quantity applied on a surface, and many other factors can extend its curing time. A standard curing time is seven days but if applied on floors it can be ready for use in 12 hours.

- Melap Portugal — guia de casinos online licenciados e também sites para apostas dentro de território português

- International Dating Challenges: How to SolveThem

- Znaki Sverige: nyheter om de verksamheter som påverkar den moderna världsbilden

- Best Pills for Erection: Your Comprehensive Guide to Enhanced Performance

- TOP 6 Epoxy Resin Applications in 3C Electronics Industry