China has been a leading producer of epoxy resin for many years. The application of epoxy resin has expanded far beyond its original

use in the manufacture of laminated boards and furniture.

Today, epoxy resin is used in a wide range of industries,

including construction, automotive manufacturing, and even food production.

This comprehensive guide will explore the many uses of epoxy

resin and discuss how it can benefit your business.

9 Of The Highlight Of Epoxy Resins

Epoxy resins are a type of polymer that is come from two or more epoxide groups.

Epoxy resins are a group of materials that can react together. They all have the same type of reactive group, called an epoxy or oxirane group. These resins are strong, resistant to chemicals, and have other special properties.

Epoxy resin has high chemical resistance

Epoxy resin has heat resistance

Epoxy resin has easy adhesion on a wide variety of substrates

Epoxy resin has high compression, bending strengths, and tensile

Epoxy resin has a low shrinking rate during the curing reaction

Epoxy resin has high electrical retention and thermal conductivity

Epoxy resin has high abrasion resistance and corrosion resistance

Epoxy resin can cure under different temperature ranges including room temperature

Epoxy resin has a high fatigue resistance

Epoxy resins using in many different kinds of products

because they have lots of good qualities.

The Fact Of Epoxy Resin

Uncured epoxy resins are polymers that contain many epoxy groups.

They are usually found in the form of epoxides, which are

compounds with two oxygen atoms linked to a single carbon atom.

Epoxy resins begin to cure when exposed to heat or catalysts. They can also cure at room temperature.

As epoxy resin cures, it forms a rigid plastic material that is

chemically resistant and has good electrical

Epoxy resins, also known as epoxies are made of long chains of molecules to connected to each other. This process uses curing agents, also known as hardeners.

The term epoxy resins can refer to both the cured end product and the uncured resin.

Epoxy resins can be in different states – solid, liquid, or dissolved. Usually, they are liquid at room temperature but turn into a sticky liquid when heated.

When epoxy resins are cross-linked, they become hard and strong. This makes them resistant to wear and chemicals, stable in size, and good at insulating.

Is epoxy resin toxic?

Cured, hardened epoxy is not toxic.

Overexposure to resins and curing agents used before the epoxy is cured

may cause eye, nose, throat, or skin irritation, as well as skin allergies and asthma.

Exposure to solvent additives in epoxy resin systems can cause

headaches, dizziness, and confusion.

If you breathe in solvents or they touch your skin, it can also hurt your nervous system.

Other signs that you have been exposed to too much solvent include being able to speak,

being confused, and passing out.

If you wear the right kind of clothing while you are working with epoxy resin,

it can help keep the solvent from hurting you as much.

The Varieties Of Resins Hardeners

There are epoxy resins and hardeners that come in different forms.

Use together to make epoxy products with various properties.

The most common epoxy resins are epoxide, vinyl ester, and novolac epoxies.

Epoxide epoxies have excellent resistance to chemicals and heat but lack impact

Many different types of hardeners or co-reactants can be used with epoxy resins.

This includes amines, acid anhydrides, phenols, alcohols, and thiols.

Each one has its special properties. Acid anhydrides are used in the manufacture of industrial chemicals. When the epoxy resin reacts with fatty acids derived from oils, it produces epoxy esters.

These can be air drying or non-air drying.

Amines are the most common epoxy hardeners because of their low cost and good properties.

They provide epoxy with a strong bond that is resistant to heat, water, and chemicals.

Phenols are used in specialty epoxies such as those used for high-temperature applications.

Alcohols react slowly with epoxy resins, making them ideal for epoxy coatings.

Thiols provide high chemical and heat resistance but are not

recommended for outdoor use because they are sensitive to UV light.

Main uses of epoxy resin

Epoxy resins have many uses, including:

•electronics manufacture- epoxy is often used to bond components

together in electronic devices and circuit boards

•injection molding- epoxy is used to make molds for plastic parts

•protective coatings- epoxy can apply as a protective coating to

metal surfaces, such as ships and cars

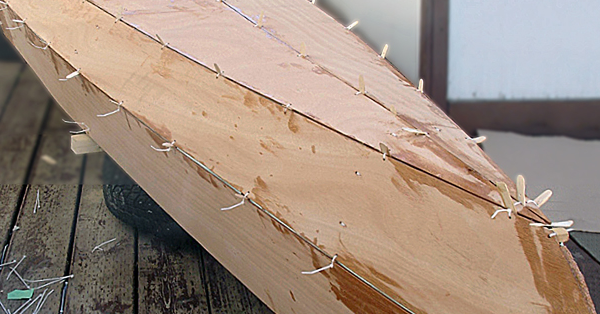

•marine and boat construction- epoxy is often used in the

construction of fiberglass boats and other marine vessels

•woodworking- epoxy can be used to strengthen the wood,

protect it from water or moisture damage, or give it a decorative finish

•China manufacturing- epoxy is often used in the production of china products.

due to its strength, heat resistance, and chemical resistance

Safety Information

Epoxies have undergone extensive testing for health and environmental effects.

Even though epoxy is not active and not harmful, some of the things used to make it could be harmful. This means they could cause problems or make people sensitive.

Epoxy systems can be safe if people take some basic safety precautions and follow specific safety instructions.

Epoxy resins are primarily used in building and construction applications.

If workers do not have the right kind of safety gear or tools, they may expose to dangerous chemicals.

You may get sick if you touch or breathe in epoxy resins.

This can happen when you are transporting, mixing, spreading,

spraying, or rolling epoxy components.

You can also get sick if you are around empty containers or waste materials. If you touch uncured epoxies, it can make your skin red and sore.

The correct use of personal protective equipment (PPE) and skin

protectant can help protect workers from skin contact.

Seek guidance on the safe handling of epoxy resins in industrial settings.

Observing these simple safety precautions helps stay safe while handling different epoxide groups.

Is Epoxy Expensive?

Epoxy is not expensive; In the United States, a gallon costs from 80$ to 150$.

while if you purchase from China, it will be much cheaper, one of

the supplier’s RESINOO will be as low as 20$ to 30$ a gallon. in fact, it’s one of the most cost-effective materials used in manufacturing. It can be used to make products that are durable and long-lasting, which helps save money over time. As epoxy technology advances, epoxies become even more affordable and efficient.

Why the cost difference is so big between the U.S and china?

The cost difference between epoxy in the United States and epoxy in China,

is largely due to differences in labor costs, shipping costs,

government regulations, currency exchange rates,

and bulk purchasing power.

If you are looking for a cheaper alternative to epoxy resin, polyester

and vinyl ester is the ideal option.

The best way to identify the most suitable alternative is to

understand the epoxide groups.

Impact Of Temperature

Epoxy resins are sensitive to temperature,

and it is important to know the properties of epoxy,

when exposed to different temperatures.

Exposure to extreme temperatures

can make epoxy brittle or sticky, affecting its strength, durability, and performance.

High temperatures cause epoxies to become more pliable and soft,

while low temperatures cause epoxies to become brittle and hard.

You should always keep an eye on the temperature

of the area around you, as well as the surface temperature and the temperature of the epoxy resins as they cure.

Some epoxies need to be cured by exposure to ultraviolet light,

and these are commonly used in optics, fiber optics, and optoelectronics.

The shelf life

Epoxy resins have a shelf life of several years

when they are stored correctly at room temperature in sealed containers. This prevents the epoxy resin from being contaminated.

How To Choose Epoxy

There are some factors you should consider to get a good epoxy system.

The Use

When choosing epoxy resin, it is important to think about what you will use it for. Epoxy resin can use for simple or more complicated projects.

The Work-life

The work-life of an epoxy resin is a great way to determine which one is most suitable. It determines how long it can stay in a workable state before it dries. You can plan the time and quantity to mix ahead of time with this information.

The Curing Time

When you are using epoxy resin, it is important to consider how long it will take for the resin to harden. This will help you determine how much resin you need to mix when application size.

Temperature

Think about how hot or cold it will be where you use the epoxy resin product. It should work in both room temperature and extreme temperatures. Adding carboxylic acids can help the resins cure faster.

Paints and Coatings

Epoxy resin is a type of material that use in paints and coatings. It is strong and can last for a long time, even in bad weather conditions.

Epoxy resin-based products are also resistant to mold and mildew,

making them a good choice for painting bathrooms and kitchens.

Food Packaging

Epoxy resins are also used in food packaging to ensure the safety and freshness of food. Epoxy resin is non-toxic, making it a safe choice for food packaging.

It is also resistant to thermal changes,

which helps protect the food from spoilage and contamination.

Molding and Casting

Epoxy resin is also used for molding and casting.

It’s an ideal material for crafting items such as jewelry and figurines,

as epoxy resin can easily be poured into intricate molds.

This makes it a great choice for complex designs,

because epoxy resin does not shrink when it cures,

making the finished product look exactly like the mold.

Does Epoxy Resin Stick During Moulding And Casting?

Epoxy resin does stick when used in molding and casting. Yet, it is important to use the correct release agent to prevent the epoxy from sticking. Release agents are generally sprayed onto the surface of a mold before epoxy resin is poured into it.

This helps ensure that epoxy doesn’t adhere to the mold and makes

it easier to remove the final product from the mold.

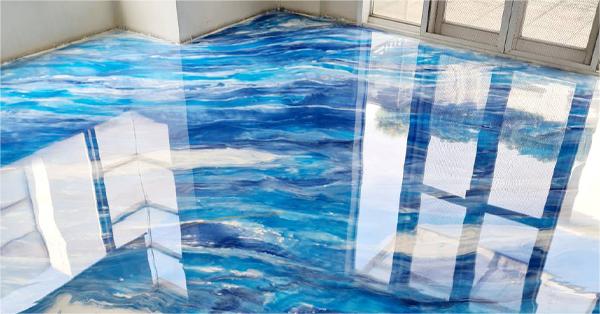

Concrete Flooring

Epoxy flooring is a type of flooring that is made from epoxy resin. It is a popular choice for homes and businesses because it is

durable, easy to clean, and resistant to stains and scratches. Epoxy flooring is also non-toxic, making it a safe choice for indoor use.

Epoxy flooring is installed by pouring epoxy resin onto the surface

of the floor and then spread it out evenly with a roller.

The epoxy resin will then cure and harden, creating a durable and

tough surface that can withstand heavy traffic.

Epoxy flooring is available in a variety of colors and styles, making it a versatile choice for any space. It can be used in homes, businesses, schools, hospitals, garages, and other public spaces.

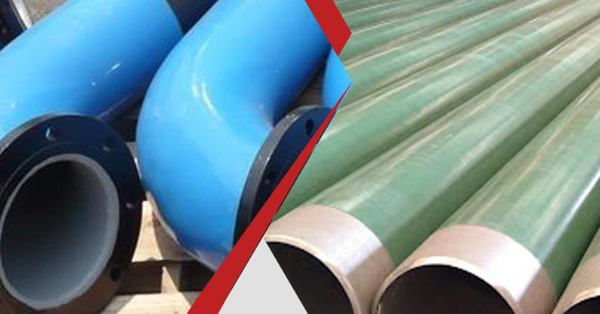

Plumbing and Pipes

Epoxy resin is also used for pipe coating. Pipe coatings are used to protect pipes from corrosion and other damage. They also help to improve the flow of fluids through the pipe.

epoxy resin-based coatings are a popular choice because they are

durable and resistant to most chemicals.

High-Performance Adhesives

Epoxy resin is a type of glue that is used in high-performance adhesives.

These adhesives are designed to be stronger than other types of

glue, and can withstand extreme conditions.

Epoxy resin-based adhesives are a popular choice because they last

a long time and are resistant to most chemicals. They are also very flexible, which means they can be used for many different things.

Automotive

Epoxy resin is a popular choice for automotive applications because

it is strong and durable.

It can withstand extreme temperatures and weather conditions and

is resistant to most chemicals.

Epoxy resin products are also resistant to mold and mildew, making

them a good choice for automotive applications.

Epoxy resin is the preferred material for potting battery

components because it is strong and can seal out moisture.

The new energy industry relies on epoxy resin for potting,

and encapsulation of battery components to keep them from

coming into contact with the environment.

The market rise of epoxy resin in China has been attributed to the booming energy industry.

Sports and Leisure

Epoxy resin is a type of glue that is used to make things stronger.

It is combined with materials like carbon fiber to help it withstand

industrial processes, and to produce sporting equipment that is both strong and flexible.

Epoxy resin is also lighter than other types of glue, which makes it perform better.

Some of the equipment that is made with epoxy resin includes skis,

tennis rackets, hockey sticks, and golfing equipment.

Resin is also used as a coating for kayaks, bicycles, jumping poles,

archery bows and arrows, and fishing poles and rods.

Epoxy resin has coatings that are used on boats. They are excellent adhesives, highly resistant to moisture absorption, and strong abrasion resistance.

Sealant

One of the greatest properties of epoxy resin is that is waterproof and moisture-resistant.

This multiplies epoxy resin’s good adhesion properties and filling properties.

It enhances the ability to seal and form a waterproof protection

layer with chemical resistance strength and good weather resistance.

Entropy resins an epoxy resin sealant is ideal for engineering

adhesives andglycosylationdhesives and is available in different hardware stores.

Epoxy resin diluents are typically formed by glycidylwork of

aliphatic alcohols or polyols and also aromatic alcohols.

Glycidyl ethers such as dodecanol glycidyl ether works as a polymerization reaction monomer.

Aerospace

Epoxy resins are used to help make aircraft and satellite systems strong and lightweight.

The resins are a binder for reinforcements such as glass and carbon.

They can also be made to resist the extreme temperatures experienced by aircraft and can help make structural parts last longer.

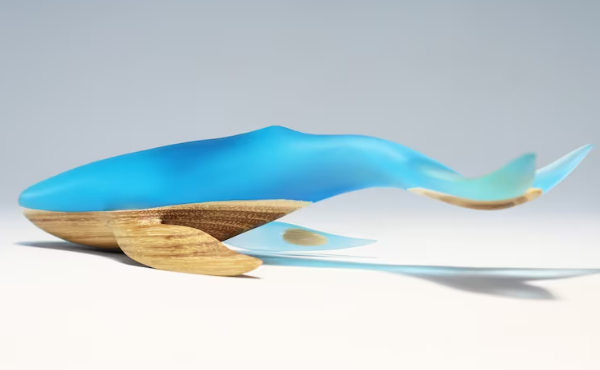

Consumer Marines

Epoxy resin is also used in marine applications. It can be used to make boats stronger and more resistant to the elements.

Solid epoxy resin coatings are used on boats to help protect them from the sun, weather, and salt water.

Epoxy resin is also used to make boat parts such as propellers, rudders, and hulls.

epoxy resin is an excellent adhesive and can withstand the harsh

conditions in the marine environment.

Electrical Engineering

Liquid potting epoxy resin is also used in the manufacture of electronic equipment.

The epoxy resin helps to protect the equipment from the extreme conditions that it can be exposed to.

It also helps to keep the equipment together and prevents it from breaking.

Epoxy resin is also used as a sealant in electronic equipment to keep moisture and dust out.

Epoxy resin has been used for about 60 years in electrical applications. Deep pour epoxy resin is used to make high-performance electrical components.

Brominated bisphenol epoxy resin is a type of epoxy resin that has a low molecular weight,

and low dielectric constants, making it ideal for electrical applications.

Insulation

Entropy resins are epoxy resins that have low thermal conductivity.

This makes them good at resisting heat and ideal for electrical applications.

They are mainly, used in the manufacture of electrical components

such as switchgear, printed wiring boards, bud-ducts, drives, disconnectors, rolling stocks,d generators.

Electrical Components

Epoxy resins are also used in the manufacture of other electrical

components such as coils, transformers and motors.

epoxy resin is used as an insulation material to protect against

elec, and tric shock and prevent sparks from forming. epoxy resin is also

used to coat bearings and provide a layer of protection against dirt,

microbes, oil and moisture.

Epoxy resins have been used to make electric components that are

well-insulated, lightweight, and durable. These components are also resistant to a variety of environments and chemicals.

Carbon Fiber Reinforcements

Epoxy resin can be used to create carbon fiber reinforcements.

The epoxy resin is first put on the carbon fibers and then it is heated up to make it strong.

This helps the epoxy epoxy-reinforcers stay together better so it is stronger.

This technology has enabled manufacturers in China to produce

stronger and lighter cars with epoxy reinforced materials.

Epoxy resin is a popular choice for automotive manufacturers

because it is strong and lightweight.

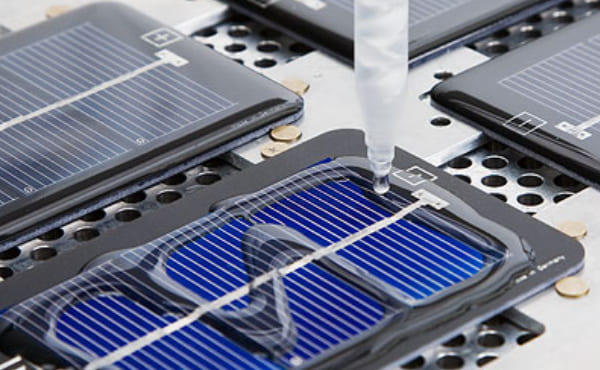

Solar Energy

Epoxy resin is a material that can be used for solar energy applications.

For example, it can be used to bond the photovoltaic cells onto the frame of solar panels.

Additionally, epoxy resin can help protect the photovoltaic cells

from harsh weather conditions and UV radiation.

Finally, epoxy resin can also be used as a sealant to prevent

moisture and dust from seeping into the photovoltaic cells.

Epoxy resin is used to keep solar panels strong and resistant to damage.

It is also used to make solar thermal collectors and mirrors. Using epoxy resin can help make solar energy systems more efficient.

Solar energy is a type of renewable energy that has been getting more popular recently.

People like it because it doesn’t produce pollution that causes global warming.

Solar panels are placed outside, so they need to be strong enough to

withstand the weather conditions.

Solar equipment is exposed to very low temperatures, hot weather,

lots of rain, UV rays, storms, hail, and strong winds. To make the solar equipment last longer in these conditions, it is sealed with a coating of epoxy resins.

This helps the solar equipment withstand extreme conditions better.

Epoxy resins are strong, adhere well, and have low molecular weight. They also offer dimensional stability.

These properties make epoxy resin ideal for protecting solar

equipment against environmental hazards and chemical damage.

In Summary

Epoxy resins have many applications and can be used in a variety of industries.

It is used to make high-performance electrical components,

insulation materials, carbon fiber reinforcements, and solar energy equipment.

Epoxy resin is strong and lightweight, making it ideal for protecting

electronic components from wear and tear. Additionally, epoxy resins offer protection against harsh weather conditions and UV radiation.

Epoxy resin is a durable and long-lasting material that is also environmentally friendly.

Solar energy equipment is more efficient and able to withstand

extreme environmental conditions thanks to epoxy resin. For these reasons, epoxy resin has become an essential material for many industries.

For more information about epoxy resins and their various

applications, contact your local epoxy resin supplier.

They can provide you with the best epoxy resin for your specific needs.

- Melap Portugal — guia de casinos online licenciados e também sites para apostas dentro de território português

- Znaki Sverige: nyheter om de verksamheter som påverkar den moderna världsbilden

- Best Pills for Erection: Your Comprehensive Guide to Enhanced Performance

- TOP 6 Epoxy Resin Applications in 3C Electronics Industry

- The Role of Epoxy Resin in Enhancing Electronics: Applications and Benefits