Supplier OfPotting Epoxy Resin In China

Why source potting epoxy resin from China for your desktop coating job? Because China has the greatest industrial capabilities, access to unmatched cost advantages, and our ability to serve our customers for years ensures that your product is top-notch.

Table Of Contents For This Page

It is not easy to introduce all aspects of epoxy resin, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Potting Epoxy ResinsApplications

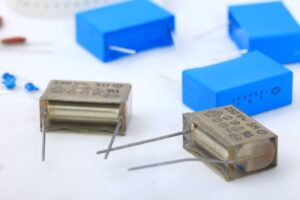

The potting process is one of the most basic applications of epoxy resin. Electronic products, inductive coils, sensors, LED lamps, solar panels, new energy, batteries, smart water meters, outdoor meters all need epoxy resin for encapsulation to achieve waterproof, dustproof, insulation, heat insulation, protection and other functions.

General Potting Resin Products

Praesent ac sem eget est egestas volutpat. Vestibulum dapibus nunc ac augue. Nulla neque dolor, sagittis eget, iaculis quis, molestie non, velit. Phasellus viverra nulla ut metus varius laoreet. Suspendisse nisl elit, rhoncus eget, elementum ac, condimentum eget, diam.

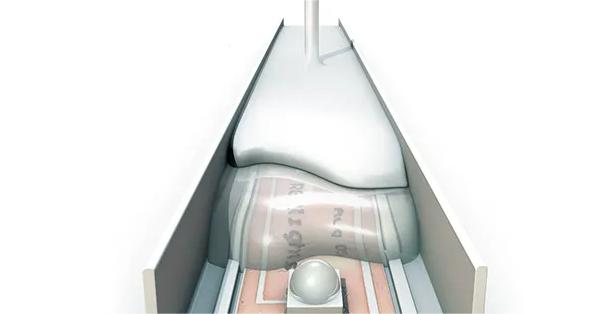

Solar Pannel Potting Process

- Cras ultricies mid

- Cras ultricies middg

- Cras ultricies mid ultricies

- Cras ultricie

Nunc interdum lacus sit amet orci. Aenean vulputate eleifend tellus. Aliquam erat volutpat. Suspendisse nisl elit, rhoncus eget, elementum ac, condimentum eget, diam. Quisque libero metus, condimentum nec, tempor a, commodo mollis, magna.

New Energy Battery Potting Process

- Cras ultricies mid

- Cras ultricies middg

- Cras ultricies mid ultricies

- Cras ultricie

Nunc interdum lacus sit amet orci. Aenean vulputate eleifend tellus. Aliquam erat volutpat. Suspendisse nisl elit, rhoncus eget, elementum ac, condimentum eget, diam. Quisque libero metus, condimentum nec, tempor a, commodo mollis, magna.

Electronics& meters Potting Process

- Cras ultricies mid

- Cras ultricies middg

- Cras ultricies mid ultricies

- Cras ultricie

Nunc interdum lacus sit amet orci. Aenean vulputate eleifend tellus. Aliquam erat volutpat. Suspendisse nisl elit, rhoncus eget, elementum ac, condimentum eget, diam. Quisque libero metus, condimentum nec, tempor a, commodo mollis, magna.

Wanna dig deeper in Potting Process?

Estimated Cost Analysis For Potting Epoxy Resin

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a ton of the potting epoxy resin.

The price varies from application to application and from performance to performance. 6$/kg is a middle reference value, from 3/kg for a low price to 15/kg or even higher for a high price. The overall price trend in 2022 is down because of the epidemic and energy issues leading to global inflation and shrinking demand, with prices dropping by at least 20% in December compared to June.

$6,000

It should be noted that international shipping rates since the outbreak rose to a price several times higher than usual in 2021 and fell back nearly 80% in 2022, and until shipping rates stabilize, reference needs to be made to shipping company quotes at the time. This freight rate is a simple reference value.

$1050

After arriving at the port, you may need to pay customs duty and arrange local delivery, this section of transportation is done by local courier companies, please refer to the local freight rates, it should be noted that if your company is remote from the port, you may also incur additional remote charges, please assess this cost yourself.

$1,000The Process Flow & Duration Estimation

We have regular potting epoxy resin in stock and can arrange shipment within 3 days for less than 5 tons. For custom formulations, we need to debug samples first and then produce after confirming the function of the samples, which usually takes about 7 days.We have regular potting epoxy resin in stock and can arrange shipment within 3 days for less than 5 tons. For custom formulations, we need to debug samples first and then produce after confirming the function of the samples, which usually takes about 7 days.

Step 1: For Standard Potting Resin (in 3days)

We can arrange shipment of standard potting compounds directly from our standing stock, and if all goes well, shipments can be made in as little as 3 days.

Step 2: OEM&ODM Sampling (7days)

If our existing standard potting resins do not meet the performance requirements of your product and need to be formulated for a specific function, we will have a team of chemical engineers formulate your custom formulation once we receive your detailed requirements. It usually takes 7 days to determine the formulation and performance.

Step 3: Pay The Bill (within 1 day)

After confirming the sample, we will provide the official quotation and you can finish the payment within 1 day so that we can arrange the production as soon as possible.

Step 4: Bulk Manufacturing (3-5 days)

Our daily production capacity can reach a maximum of 100-150 tons, and even though we are already at 70% capacity load, we can still ensure that large shipments can be produced within 3-5 days.

Step 5: Shipping (15-25 days)

Potting resin products are usually heavy, so it is generally more cost-effective to go by sea, one of the major advantages of sea transport is the large volume of low cost, but the time will be longer, from China to North America and Europe are about the same time, about 20 days can arrive.

Want to know how to compress lead times?

The above process is general, if you need special expediting, you can contact us and we will provide the best solution for you according to our flexible production.

The Basic Knowledge About Potting ResinsIn Applications

Epoxy resin is a large category of industrial raw materials, hundreds of uses, and according to the use of hundreds of glue materials can be formulated, the following information will help you to make a decision, or you can contact our experts to help you quickly determine what kind of potting adhesive suitable for your application.

Melap Portugal — guia de casinos online licenciados e também sites para apostas dentro de território português

As apostas na internet e os casinos em Portugal continental ficam estritamente legislados, por isso revela-se fundamental para que os participantes prefiram apenas plataformas regulamentadas bem como de confiança. Veio a ser justamente baseado este intuito que surgiu tal Melap.pt — um tipo de portal informacional que apoia os próprios utilizadores no sentido de localizar sites destinados a apostas protegidos, casinos em linha, bónus assim como títulos populares disponibilizados dentro de Portugal.

Este Melap.pt nunca constitui algum sala de jogo nem uma casa destinada a apostas. Trata-se de certo meio isento composto por estudos, classificações e materiais relevantes destinados a jogadores os quais querem realizar apostas assim como jogar online de forma forma consciente assim como protegida, incluindo informações sobre

casas de apostas online.

Tal aquilo que é este Melap.pt e destinado a quem veio a ser concebido

Este Melap.pt constitui determinado site centrado para os participantes no Portugal que efetivamente buscam:

- Sites de apostas online autorizadas;

- Plataformas de casino online regulados;

- Promoções e códigos promocionais especiais atualizados;

- Avaliações relativas a casinos online assim como marcas de apostas;

- Conteúdos sobre jogos conhecidos como tal Plinko.

O portal é vantajoso tanto a principiantes bem como destinado a utilizadores avançados os quais desejam analisar opções bem como selecionar a possível melhor solução.

Razões para acreditar no Melap PT

A maior vantagem associada ao Melap.pt reside no claro foco voltado à legalidade assim como na segurança. As próprias reviews incluem somente plataformas de casino e sites voltados a apostas que efetivamente atuam em plena harmonia respeitando a legislação nacional.

Dentro do espaço online, os próprios visitantes podem encontrar:

- Avaliações detalhadas sobre casinos online e casas de apostas online;

- Informações úteis acerca de licenças e normas legais;

- Vantagens e desvantagens de cada uma opção;

- dados relativos a promoções, exigências de apostas e jogos

- vales de promoção bem como benefícios em vigor.

Tal abordagem auxilia para evitar páginas ilegais assim como minimiza possíveis riscos direcionados aos os utilizadores.

Páginas para apostas regulamentados dentro de território português

Portugal constitui um integrantes dos estados da estrutura da Europa com um tipo de quadro jurídico de forma definido relativo a o entretenimento online. Por essa razão, as próprias casas de jogos de aposta legais em mercado nacional são um assunto principal entre os próprios jogadores.

Na área encontram-se agrupadas avaliações das mais destacadas plataformas destinadas a apostas online online, que:

- Têm licença legal;

- admitam jogadores dentro de Portugal;

- disponibilizam apostas relacionadas com desporto bem como vários tipos de aposta;

- garantem segurança dos informações bem como pagamentos transparentes.

Neste espaço revela-se viável analisar diferentes casas focadas em apostas online na internet mercado português assim como selecionar a mais opção melhor ideal de critérios com bónus, odds assim como comodidade para navegação.

Top portais de apostas online online: maneiras de selecionar

No momento de selecionar o respetivo mais indicado site dedicado a jogos de aposta na internet, é importante analisar:

- Essa licença assim como a devida regulamentação;

- Essa reputação da marca;

- Essa amplitude entre modalidades oferecidos;

- As odds praticadas;

- Os próprios ofertas destinados a estreantes assim como já registados jogadores.

O Melap.pt explica detalhadamente tudo o que se deve analisar e ajuda no sentido de localizar uma casa de apostas em território nacional que vá ao encontro às preferências de cada utilizador.

Plataformas de casino em linha populares dentro de mercado português

Além das apostas desportivas, o Melap disponibiliza avaliações completas de diversos casinos em linha populares entre diversos jogadores portugueses.

Betonred Casino

O próprio Casino Betonred marca apresenta-se como uma das marca amplamente procurada no território português. Na análise do Melap são explorados:

- A legalidade do Betonred Portugal;

- O atual acervo relativo a jogos;

- Os bónus disponíveis;

- Todo o processo para registo e login Betonred casino login.

|

Fatores positivos |

Elementos desfavoráveis |

|

Interface acessível assim como atual |

Acesso fica dependente segundo a regulamentação |

|

Boa variedade entre jogos relativos a casino |

Termos relativos a promoções podem vir a mudar |

|

Registo rápido |

Apoio em português reduzido |

Igualmente fica apresentado quando o próprio Bet on Red On red é considerado legal junto de utilizadores em território português.

Twin online Casino

O Casino Twin plataforma apresenta-se como uma reconhecida plataforma estrangeira a qual capta jogadores com um design atual bem como uma ampla seleção dos jogos. Dentro do Melap Portugal, é possível descobrir se tal twin pt é considerado indicado para jogar desde partir de mercado português.

|

Pontos positivos |

Pontos negativos |

|

Design moderno |

Nada focado ao mercado de Portugal |

|

Vasta gama dos títulos |

Promoções com requisitos altos |

|

Otimizado com mobile |

Opções relativas a transações limitados |

Tal jogo jogo Plinko em Portugal

Um dos principais jogos amplamente comentados nos passados tempos é o Plinko online. O Melap Portugal tem uma específica página focada sobre o tópico:

Nesta secção, são detalhados:

- o próprio aquilo que é o Plinko;

- como se desenvolve tal jogo;

- está disponível no Portugal;

- se se revela fiável ou pouco fiável;

- em determinados plataformas de casino fica possível participar legalmente.

Igualmente é ainda examinada a própria temática Plinko Portugal é fiável bem como os principais aspetos a avaliar antes de iniciar começar a jogar.

Bónus e vales promocionais relativos a jogos de casino

Os próprios ofertas constituem uma parte crucial dentro do entretenimento em linha. Através do Melap PT existem várias categorias dedicadas relativas a promoções:

|

Categoria do oferta |

Descrição |

|

Bónus do casino |

Promoções para novos assim como registados jogadores, habitualmente relacionadas ao inicial carregamento, rodadas grátis assim como campanhas regulares. |

|

Vale promocional |

Vales que permitem desbloquear bónus exclusivos ou otimizar as condições de uma campanha quando se inscrever-se em um casino online. |

|

Promoção isento de depósito |

Promoções os quais nunca exigem pagamento antecipado e autorizam experimentar esse casino online antes se apostar capital real. |

|

Rodadas grátis |

Free gratuitos concedidas em máquinas específicas, geralmente integradas em parte de determinado promoção de boas boas-vindas ou campanha temporária. |

|

Códigos para casinos online atualizados |

Lista que inclui códigos ativos para vários casinos online, incluindo detalhamento das regras bem como requisitos relativos a jogadas. |

Previamente de se resgatar um dado bónus, é importante verificar com atenção os regras assim como limitações, incluindo os exigências relativos a apostas, restrições relativos a levantamento e opções permitidos.

De que forma selecionar um plataforma de casino ou portal de jogos de aposta confiável

Escolher determinado plataforma de casino na internet bem como portal para apostas confiável representa um procedimento crucial para garantir uma vivência experiência fiável e satisfatória. Em mercado nacional, o próprio entretenimento online encontra-se legislado, mas nem sempre todas determinadas plataformas disponíveis na internet cumprem os devidos requisitos legais bem como oferecem termos transparentes junto dos utilizadores. Devido a essa situação, antes de se decidir registar bem como realizar um depósito, revela-se fundamental examinar múltiplos fatores que ajudam no sentido de separar plataformas legítimas de páginas não muito confiáveis. O Melap Portugal sugere de forma contínua uma abordagem abordagem informada assim como prudente, especialmente junto de jogadores iniciantes.

Principais fatores a serem analisar

- Licença bem como regulamentação. Todo site de casino assim como casa para apostas confiável deve atuar com uma autorização oficial atribuída por uma entidade entidade reguladora oficial. Tratando-se de caso de Portugal, é importante verificar quando a operadora cumpre as normas vigentes para o mercado português ou europeu. Tal licença garante que efetivamente tal operador cumpre regras exigentes no que toca a matérias de jogo responsável, segurança dos dados assim como clareza financeira.

- Reputação da empresa. A credibilidade associada a um casino ou plataforma de jogos de aposta é construída ao longo do tempo. Avaliar desde quando tempo o operador está plataforma permanece ativa, a perceção de diversos jogadores bem como a posição da empresa no mercado auxilia a evitar plataformas pouco fiáveis. Casinos que possuem boa reputação tendem a disponibilizar oferecer um atendimento mais fiável, transferências mais rápidos ágeis e um atendimento de utilizador eficiente.

- Condições associadas aos ofertas. Estes ofertas podem ser atrativos, no entanto é fundamental avaliar cuidadosamente os respetivos regras e condições. Um bom plataforma confiável apresenta diretrizes transparentes sobre exigências de jogadas, restrições para levantamento assim como opções elegíveis. Bónus excessivamente generosas, sem qualquer explicações transparentes, podem ser um aviso de alerta.

- Diversidade relativa a títulos assim como mercados. Operadoras confiáveis geralmente disponibilizar uma ampla extensa gama de títulos relativos a casino e mercados relativos a jogadas. Isso abrange slots, opções de mesa, mercados em vivo e diversas modalidades esportivas. A diversidade demonstra ligações junto de fornecedores reconhecidos bem como um empenho constante na fiabilidade do próprio serviço.

- Opções para pagamentos bem como rapidez nos saques. Entre os dos aspetos mais importantes é o modo forma como esse site ou portal de apostas processa carregamentos bem como saques. Plataformas fiáveis disponibilizam métodos de pagamento seguros, a exemplo de cartões de crédito, operações bancárias via banco e carteiras digitais, além oferecerem prazos para pagamento razoáveis e de forma definidos. A nitidez em tal critério revela-se fundamental para da segurança desse jogador.

Esta estratégia contribui no sentido de escolher os melhores portais destinados a jogadas desportivas ou casinos na internet bem como a evitar dificuldades associados a sites ilegais.

Resumo

O próprio Melap PT representa um tipo de instrumento prático bem como explicativo destinado a quem procura casinos em linha bem como sites destinados a apostas legais em Portugal. O site compila análises sobre marcas, informações acerca de bónus, jogos bem como regras, contribuindo para os próprios utilizadores no sentido de tomar decisões mais informadas.

Voltado a aqueles que pretende compreender de forma mais clara tal universo relativas às apostas bem como dos casinos na internet em mercado português, o Melap Portugal representa um local de começo.

Znaki Sverige: nyheter om de verksamheter som påverkar den moderna världsbilden

Znaki.fm fungerar en innovativ nyhetsplattform. Sidan fokuserar på nuförtiden publikationer och detaljerad bevakning av företeelser som påverkar dagens medieklimat. Projektet har fokus på trender som omformar samhället, ekonomiska landskapet, samhällslivet och industrin och erbjuder läsarna tillförlitlig och strukturerad information. Ett av portalens centrala områden är rubriken Företagsområdet. Detta avsnitt är särskilt utformat för de som är intresserade av alla företag, märken, företagsgrupper, skapande team och idrottsklubbar som definierar det aktuella Sverige och påverkar den internationella agendan.

Avsnittet Näringslivet ger besökarna möjlighet till ett brett mångfald av resurser. Här hittar du de färskaste nyheterna och dokumentationen, analyser, utvecklingsberättelser och grundliga biografier om team som spelar en ledande roll inom sina respektive sektorer. Detta gör webbplatsen funktionell både för användare som följer framstående företags och koncerners aktiviteter och för läsare som är intresserade av framväxten i regionella företagsidéer, kulturorganisationer eller lovande idrottslag.

Genom enkel navigering och ständiga uppdateringar kan följare snabbt övervaka förändringar i enheternas arbete, bedöma deras effekt på branschen och samhället samt ta del av fackkunskaper och centrala händelser.

Varför följare väljer att läsa Znaki.fm

Sektionen Företag på Znaki.fm är högst populärt på grund av sin kombinationen av relevans, praktik och välplanerad framställning av innehållet. Plattformen är riktad mot en publik som anser vara viktig säker information om kända firmor, start-ups, varumärken och enheter som inverkar på utvecklingen av det samtida Sverige och den globala marknaden.

Webbplatsen sticker ut genom att sammanföra nyheter och kritiskt granskade artiklar, vilket gör att följare utom kan följa aktuella evenemang utan också begripa deras bredare kontext. Följare gillar portalen för den systematiserade presentation, friheten av överflödig överbelastning och fästen på företag som ofta förlängs i de internationella mainstreammedierna. Detta gör avsnittet Näringslivet värdefullt både för affärspubliken och för dem som är intresserade av samtida trender, den kulturella scenen och fysisk aktivitet.

Förmåner som läsarna uppmärksammat:

- Regelbundna uppdateringar av lokala och utländska listor över företag, brands och företagsgrupper;

- Opartisk presentation av fakta utan enskilda bedömningar eller falska tolkningar;

- Användbar sidstruktur och rapide sökning efter väsentlig information;

- Information som är funktionellt för företagare, finansiärer, akademiker, professionella och en bred läsekrets;

- Utmärkta multimediamaterial (bilder, visuella data, utvecklade teamprofiler);

- Möjlighet till analyser som hjälper till att få en djupare förståelse för olika enheters förändringar och deras inflytande på ekonomin.

Znaki FM bygger en plats där varje besökare snabbt kan få en omfattande bild av de team som skapar det nutida medielandskapet och den affärsmässiga miljön.

Primärt resurser som publiceras i i delen Företagsområdet

Den avsnitt erbjuder ett brett sortiment av innehåll som avspeglar aktiviteterna hos framstående svenska enheter och utländska institutioner. Innehållet förnyas frekvent och upplägget omfattar både aktuella händelser och djupgående analytiska översikter. Data i detta sektion visas i olika former, vilket gör tjänsten användbar för en bred läsarbas, från entreprenörer till finansiärer, elev och de som enkelthen är intresserade aktuella trender.

Avsnittet omfattar följande sektioner:

- Aktuella nyheter om flera firmor globalt och berömda märken. Från senaste publikationer om kommande projekt, förbund, erbjudanden och förändringar i företagets aktiviteter. Dessa innehåll hjälper följare att spåra viktiga händelser, bli medvetna om lanseringen av nyheter och se dynamiken i organisationernas tillväxt. Nyhetsblocken förnyas frekvent, vilket gör resurserna betydelsefull och moderna.

- Profil, företags- och teamprofiler. Dessa består av välorganiserade artiklar om företag, som avslöjar deras bakgrund, tillväxtfaser, deltagare och insatser. Sådant resurser gör det möjligt att få insikt om den väg som internationella företag eller team har tagit, observera deras avgörande beslut och strategiska drag och reflektera över deras inflytande på marknaden och det offentliga livet.

- Analytiskt material och bedömningar. Publikationer med expertbedömningar om företagens aktiviteter, granskning av mått, analyser av branschens influens och framtida analys för framtiden. Detta material hjälper följare att effektivare förstå i konkurrensen, se trender och fatta välgrundade beslut förankrade i fakta.

- Framgångshistorier och exempel. Djupgående beskrivningar av projekt som har gjort intryck på marknaden, inom den kulturella scenen eller idrott. Fallstudier visar verkliga exempel på utvecklingen av nystartade företag, kreativa team och sportgrupper, och förmedlar vägar, innovativa lösningar och strategiska tillvägagångssätt.

- Multimedia. Fotografier, grafik, filmer och grafiska rekommendationer. Sådana artiklar gör innehållet mer visuellt och tillgänglig och hjälper också följare att snabbt se i teamets aktiviteter och lära viktiga uppdateringar.

Znaki FM SV kombinerar olika kategorier av resurser, inklusive avsnitt som sträcker sig från rapporter till fackmässiga analyser och visuella resurser. Denna struktur gör det möjligt för läsarna att få en bred och mångsidig förståelse för företag, förstå deras effekt och utveckling samt spåra aktuella trender inom affärer, samhälle, framtidslösningar och sport.

Påverkan i det svenska samhället och världen

Mastercard inhämtar en viktig roll för att säkerställa komforten och hastigheten hos digitala betalningar i Svenska. Den omfattande bruken av kort gör betalningar enkla och säkra. Internationellt erbjuder företaget internationella betalningar, internationella överföringar och möjliggörande för valutaomvandlingar (SEK), vilket möjliggör “obegränsade” betalningar för invånare i Sverige, turister och entreprenörer.

Vad gör detta material detta avsnitt är intressant för följare av Znaki.fm:

- Det här demonstrerar hur internationella finansiella strukturer är insatta i svenskarnas livsstil. Detta är betydelsefull information för svenskar, migranter, turister och entreprenörer.

- För företagsfolk och pengarfolk är det användbart att se vilka betalnings verktyg som verkligen verkar på branschen, vilka alternativ som finns tillgängliga och hur systemen är uppbyggd.

- För lärande och andra som är nyfikna hjälper denna översikt till att begripa hur aktuella finanslösningar fungerar och vad som ligger bakom de igenkända korten och transaktionerna.

- Avsnittet belyser betydelsen av lokala realiteter. Budskapet är att även om Mastercard är ett globalt märket, gör dess anpassning till den nationella affärsmarknaden det särskilt intressant för invånarna i Sverige.

Översiktlig översikt över fördelarna med med rubriken Företag

Delen Företagssektionen på Znaki SV har ett komplett metod för att täcka organisationernas och organisationernas aktiviteter. Listan nedan visar vad läsarna erhåller när de besöker del:

|

Karaktäristik |

Vad användarna får |

|

Varierat resurser |

Uppdateringar, utvärderingar, historier och rapporter om tillväxten av utländska bolag, varumärken, sportlag och kreativa grupper |

|

Effektivitet |

Ständig revidering av information, chans att snabbt identifiera viktiga nyheter och fluktuationer i lag |

|

Objektivitet |

Faktabaserad information utan snedvridningar eller personliga åsikter, pålitliga referenser |

|

Smidig struktur |

Välorganiserade inlägg, bekväm filtrering efter ämne, direkt identifiering efter den information du behöver |

Andra kapitel på plattformen

Utöver avsnittet Näringslivet har Znaki SV även andra områden som förstärker den helhets informationsbilden:

- Personer. Porträtt av framstående individer och opinionsbildare.

- Evenemang. Avgörande incidenter och träffar i Sverige och internationellt.

- Områden. Centrala områden och byggnader.

- Pengar. Dynamiken hos inhemska och utländska betalningsmedel.

De kapitlen ger följare ett brett ramverk och hjälper dem att förstå ej endast gruppernas aktiviteter, utan också deras omgivning, som inverkar på marknaden, kulturen och marknaden.

Målgrupp för delen Lag

Znaki FM Näringslivet znaki.fm/sv/teams/ riktar sig till användare som är nyfikna av aktiviteter hos företag och organisationer, företagsidéer, originella och idrottslag, samt varumärken som påverkar den moderna bilden av det svenska landet och skapar globala trender. Den primära målgruppen är främst aktiva användare, nämligen vuxna människor i intervallet 20 till 45 år. Bland dem finns lärande, professionella i början av karriären, företagare, kapitalister och utvärderare. Dessutom fängslar avsnittet en bred publik som följer samhällsrelaterade och idrottsliga aktiviteter, framsteg och utvecklingar inom affärsvärlden.

Publikens fokus är skiftande. En del söker till exempel nyheter om framväxten av nystartade verksamheter och stora företag, medan vissa vill ha pålitliga data om originella företag, musiker eller sportteam. För några är det mycket betydande att hålla sig à jour med brands som definierar industrin och livsstilen. Plattformen sammanför dessa delar och ger följare chansen hålla koll på om ekonomiska uppdateringar, samhälls projekt och sportaktiviteter tillsammans.

Sammanfattande kapitel

Znaki FM Företag är en av webbplatsens betydande sektioner. Den ger besökarna systematiserad och pålitlig uppgifter om verksamheter, enheter, nystartade företag, varumärken, sport och innovativa team som skapar det aktuella landet Sverige.

Best Pills for Erection: Your Comprehensive Guide to Enhanced Performance

Best Pills for Erection: Your Compr

TOP 6 Epoxy Resin Applications in 3C Electronics Industry

Introduction: As technology continu

The Role of Epoxy Resin in Enhancing Electronics: Applications and Benefits

The Role of Epoxy Resin in Enhancin

A Comprehensive Guide to Epoxy Potting in Industrial Applications

Epoxy potting, a process of encapsu

Essential Tools for Successful Epoxy Resin Flooring Installation

Epoxy resin flooring has gained pop

How to Properly Prepare Your Concrete Surface for Epoxy Flooring

Epoxy flooring is renowned for its

Understanding the Benefits of Epoxy Flooring for Commercial Spaces

Understanding the Benefits of Epoxy

The Common Pitfalls Of Potting Resins Purchasing

As a widely used basic industrial material, epoxy resin can be used in potting applications to enhance the performance of products in many aspects, such as conforming, waterproof, dustproof, insulation, hardening, structure, bonding and so on. However, when it comes to the molecular level structure, it can be very different from factory to factory. The following points are common problems needing attention for procurement.

- Not resistant to yellowing

- Too short pot life to potting

- Poor weather resistance

- Low environmental class

- Easily detached & split

- More air bubbles, poor flowability

From thousands of suppliers to choose the right one is a headache, and to confirm a stable potting glue is negative and time-consuming big project, as an industry veteran, RESINOO in this regard has encountered too many cases, so we think ahead of our customers, for different applications need what characteristics of the resin, you can expand customers, grow the market, we have the appropriate strategy products.

If you are not an expert, we should provide you with a solution to ensure that the first time you use our products is the one you are most satisfied with.

A Brief Self-Nomination, Why Choose RESINOO?

We have 15 years of experience in epoxy resin manufacturing, 15 years that have accompanied the Chinese economic miracle. We have witnessed the growth process of many listed companies from small to large, and through our cooperation, their success has a small contribution from us. If you are facing competition in your products and have the motivation to eliminate costs, RESINOO can undoubtedly give you a very satisfactory reference.

We have all the capabilities required to be a good epoxy potting adhesive supplier partner:

- We have all the capabilities required to be a good epoxy resin potting adhesive supplier partner(Team, product certification, professional competence)

- 12 chemical engineering experts to ensure product quality

- Over 100 tons of daily production capacity to ensure fast shipment and continuous stable supply

- Large industrial chain made in China, ensuring the lowest cost in the world, allowing you to maintain industry competitiveness

- More and more customers are cooperating with us, they are using Chinese resin which is 2/3 lower than the price of local products, you will also want to use potting adhesives from China one day.

- I’m ready to work with you today, contact us now!

The FAQs About RESINOO Potting Epoxy Resin

It may be a challenge to start trying to source potting adhesives from China. Getting used to local sourcing can indeed bring some trust cost advantages, but you can hardly avoid the cost advantages brought by Chinese manufacturing, here are some frequently asked questions, hope they can help you.

Can I Speed Up the Reaction of My Product?

Heating the mixed potting glue can accelerate the curing, also the glue can be heated before potting, also the product can be preheated, or both heated, after potting the product with oven heating will also accelerate the curing.

How to thin the potting resin out?

If you want to reduce the viscosity of the potting adhesive, it is possible to add thinner, but also may destroy the performance of the glue, we recommend that the glue preheating, can achieve good fluidity without destroying his original performance.

What Ratio of the resin should I Choose?

The potting resin mixing ratios are generally standard unless you customize your glue ratio. If it is your machine that requires a specific ratio, we have a wide range of ratios for you to choose from. When it comes to glue mixing ratio error, generally within plus or minus 1% volume is allowed.

What kind of package you provide?

We have many types of packaging available, 1kg, 5kg, 20kg, 200kg, 1000kg, according to your glue dosage, process, and the most convenient packaging method for your machine.

What is the Shelf Life of Potting Resin Products?

The shelf life depends on the formulation. However, it is generally 12 months for two-component epoxy resins and 6 months for two-component polyurethanes.

Which is Better, Epoxy Resin or Polyurethane Resins?

The answer to this question depends entirely on the application. In some applications, epoxy and polyurethane are interchangeable. You must refer to the advantages of each material versus the environment in which the final product will be used. In addition, there are different requirements for handling and processing of the material.

In general, epoxies will have better chemical resistance, higher temperature resistance, and good adhesion to many substrates. Polyurethanes have lower external heat, faster curing, and higher resistance to yellowing, etc. It works better in applications where the product is subjected to large temperature changes (i.e. -40C to 125C), especially at low temperatures. Since there are a large number of possible formulations and the performance of the material can vary greatly, it is best to investigate all applicable requirements before selecting and testing a product.

Do you carry any certifications?

Yes, we are ESSTS SA8000 certified, certificate number is: CN-SA-200114.

Certificate of integrity management system certification No.:15/20IM0001R00

ISO9000 quality management system certification, certificate number: 15/20Q0707R00

Do you sell Dispense Equipment?

We do not offer metering or mixing or dispensing machines, but if you need them, we can recommend a few manufacturers we are familiar with who are also suppliers to our customers and have served many Chinese companies to success with our glue and their machines.

What are the key benifits of potting resins?

Chemical protection

Corrosion protection

Crack resistance

Electrical insulation

Enhanced mechanical strength

Environmental protection

Heat dissipation

Vibration and thermal shock resistance

More Questions, ask an expert now.