About Us

We have set up an industry-academia cooperation system with Sun Yat-sen University and the South China University of Technology. The company is dedicated to the research and development, production and sales of high-performance Epoxy resin, polyurethane (PU), and organic silicone materials, providing you with professional adhesive solutions. Over the past 20 years, we have served more than 5,000 customers with over 100,000 case applications, which is a testament to the reliability of our products’ performance and has helped our customers achieve great success.

Based on our extensive practical experience in emerging and traditional industries, Our products are mainly used in the new energy and automotive electronics industries for potting and sealing, in the electronics industry for potting, in the LED lighting industry for potting, in business flooring and construction sealing, in environmental industries such as water treatment, and other industries.

We have a standard industrial park in Zengcheng, Guangzhou with a number of technical staff and a new 2,540,000 ft² factory in Ningxiang, Changsha, Hunan. Our factory is ISO9001 quality system certified, IATF16949 quality system certified, and ISO14001 environmental system certified, Our factory is equipped with first-class production facilities, a professional R&D team, a first-class laboratory and testing equipment. We are coming to a leading manufacturer of epoxy resin and polyurethane (PU). Our products have been certified by ROHS, REACH, PAHS, UL, and FDA.

We provide ongoing customer support, creating a positive experience you can be thankful for. Your business investment should be one you don’t have to worry about and one that is exactly what you expected. We believe our process is a System for Success.

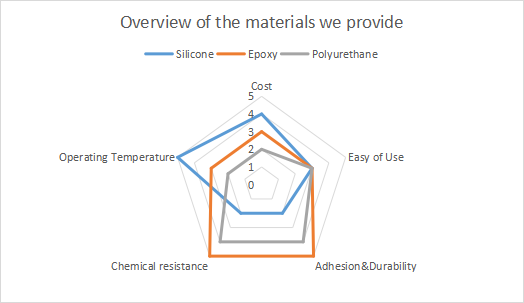

★Performance comparison of the materials based on the binder type. 5 represents the highest performance and 1 represents the lowest performance.

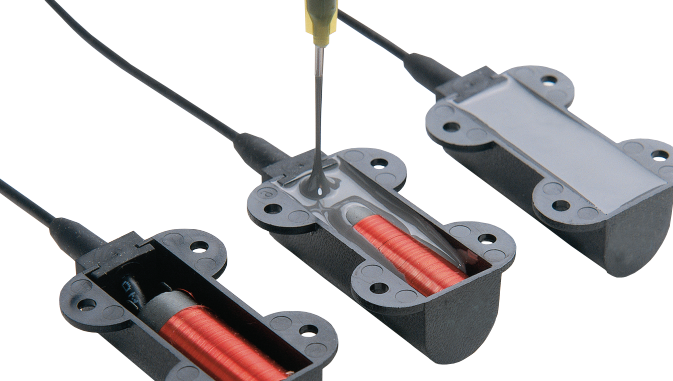

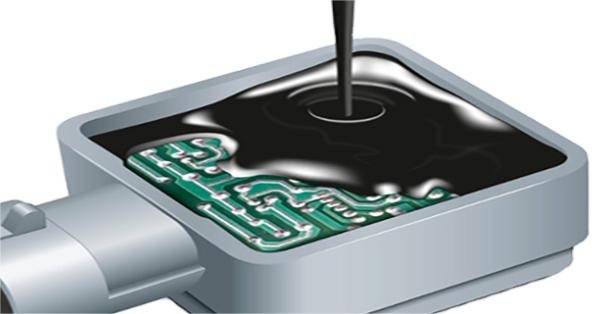

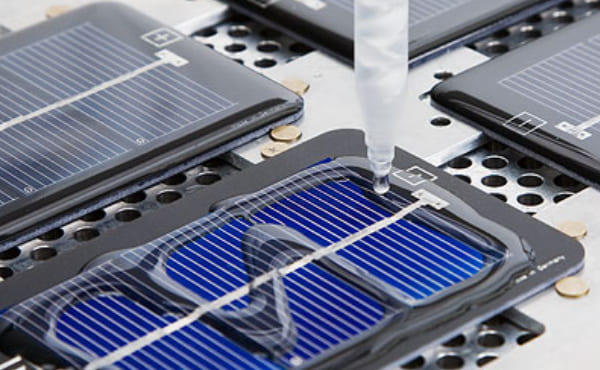

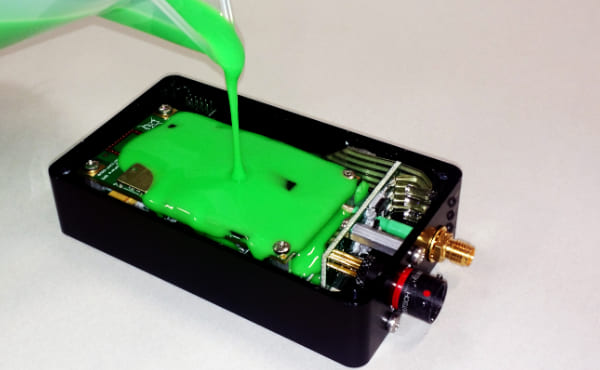

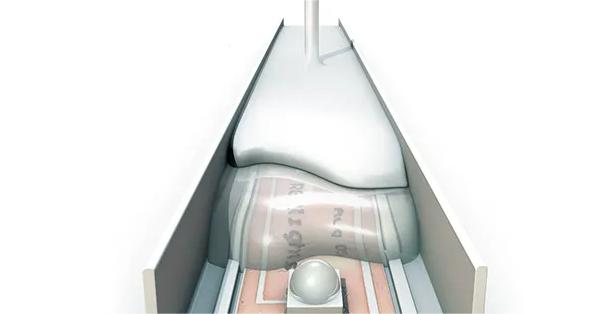

Potting compounds

| Cured Properties | RE-312 (Epoxy) | RE-6800(PU) | RE-6801(PU) | RE-6807(PU) | RE-3900(SILICON) | |

| Weight Ratio | A:B | 3:1 | 30:100 | 100:100 | 20:100 | 100:100 |

| Viscosity Part A | Mpa.s | 2300 | 200 | 80 | 250 | 3000 |

| Viscosity Part B | Mpa.s | 50 | 2000 | 400 | 4000 | 3000 |

| Pot life | Min@25℃ | 40min | 30±5 | 10-30 | 35 | 30±5 |

| Curing Time | @25℃ | 8h | 6-8h | 2-6h | 8-10h | 3-4h |

| @60℃ | 48h | 60min | 13-30min | 40min | 40min | |

| Cured properties | ||||||

| Visual Colour(Options) | B/W | B/W/Y | B/Y | B/W/Y | B/W/Gray | |

| Hardness | (Shore A/D) | 85D | 85A | 60A | 45D | 50A |

| Service temperature | ℃ | -40~150 | -40~150 | -40~100 | -40~150 | -60~225 |

| Tensile strength | N/mm2 | 30 | 20 | 18 | 25 | 23 |

| Resistivity | Ω∙cm | 1.6*10^13 | 2.6*10^13 | 2.1*10^13 | 3.5*10^13 | 1.5*10^16 |

| Breakdown voltage | Kv/mm | 25 | 24 | 26 | 26 | 30 |

| Dielectric strength | V/mil | 480 | 480 | 540 | 540 | 480 |

| Flame retardant grade | UL 94 | V0 | V0 | V0 | V0 | V0 |

Benefits&Features:

1. Good adhesion to PC, PP, PA66, ABS, aluminum, and other inquiring materials.

2 Low viscosity flooding, good flowability, no empty shell phenomenon, suitable for precision control circuit boards, full filling of voids for optimum protection.

3. Stable high and low-temperature resistance(-40℃-150℃), low internal stress, long-term use in various harsh environments, effective protection of chips and components inside the product.

4. excellent dielectric properties, meeting the 130″ CRTI standard.

5. Resilient construction for high resistance to vibration and water.water resistant to IP67 or above.

6. The curing time can be adjusted, and the curing time can be heated or at room temperature, which can improve production efficiency.

7. Package available:5kg bottle,10kg pail,20kg pail,200kg drum.

Clear Art Epoxy Resins&Deep Pour Resins

| Uncured properties | RE-1201 Epoxy | RE-318 Deep pour | RE-588 Epoxy | RE-518 PU soft | |

| Weight Ratio | A: B | 1:1 | 3:1 | 5:1 | 3:1 |

| Viscosity Part A | A: B | 2000 | 800 | 7500 | 250 |

| Viscosity Part B | Mpa.s | 1300 | 80 | 200 | 50 |

| Pot life | Min | 30min | 2h | 40min | 40min |

| Surface cured | @25℃ | 3h | 8h | 8h | 9h |

| Full cured | @25℃ | 24h | 36h | 48h | 36h |

| Cured Hardness | (Shore A/D) | 83D | 85D | 86D | 60A |

Benefits&Features:

- They are widely used for crystal photo frames, wall stickers, doming stickers, small crafts casting, drops of glue, signs, cross-stitch frame, painting frame, crafts, ornament decorations, nameplates, cards, blades, wood tables, and bar top coating.

2. High clear, Automatic de-bubbling, Yellow Resistance, High Glossy finish, Self Leveling.

3. Deep pour can be customized to use for different depths.

4. Glass or flexible can be customized as required.

5. Package available:0.5kg bottle,1kg bottle,5kg bottle,10kg pail,20kg pail,200kg drum.

Polyaspartic Flooring Resins

| Uncured Properties | RE-204 Epoxy self-leveling | RE-113 Epoxy 3D art | RE-1031 Primer Major Projects | RE-2100 Medium Major Projects | RE-5600 Polyaspartic Super Wear-resistant | |

| Weight Ratio | A: B | 2:1 | 3:1 | 3:1 | 4:1 | One component |

| Viscosity Part A | Mpa.s | 800 | 5000 | 3000 | 3500 | 3000 |

| Viscosity Part B | Mpa.s | 300 | 50 | 1000 | 1000 | – |

| Pot life | Min | 45 | 50 | 90min | 70min | 90min |

| Surface cured | @25℃ | 12h | 8h | 3h | 3h | 10h |

| Full cured | @25℃ | 24h | 48h | 24h | 24h | 36h |

| Heavy load | @25℃ | 4d | 4d | – | – | 4d |

| Hardness | (Shore A/D) | 75D | 85D | – | – | 85D |

| Cured properties | ||||||

| Visual Colour | Optional | Optional | Optional | Optional | Optional | |

| Compressive strength | Mpa | 80 | 80 | – | – | 85 |

| 3% NaCI | 7 days | √ | √ | – | – | √ |

| 10% NaOH | 48h | √ | √ | – | – | √ |

| 10% H2SO4 | 48h | √ | √ | – | – | √ |

| Lubricants | 60h | √ | √ | – | – | √ |

Benefits&Features:

- RE-204 can mix with sand, stone, pebble, and quartz, used for the garage, garden floor, and pool wall.

- RE-113 is widely used for 3d flooring, crystal floor coating, art floor, frame coating

- RE-1031 Primer is a general-purpose primer for filling gaps in large-scale commercial concrete substrates, leveling floors, and increasing the strength and adhesion of foundations.

- RE-2100 Medium is used on primer and it can be mixed with quartz sand, epoxy putty or used directly to improve the flatness and hardness of the floor, and can be mixed with pigments in different colors.

- RE-5600 Polyaspartic is the top coat that can be made with clear self-leveling epoxy resin for a glossy finish, easy to clean, or with super abrasion-resistant polyurethane for large garages, commercial centers, etc. where high abrasion resistance is required.

- Construction conditions: water content below 8% and relative humidity below 55%. Not suitable if rainy weather or atmospheric relative humidity is above 80%, or if the temperature is below 10°C.

LED LIGHT POTTING RESINS

| Uncured Properties | RE-4118 PU outdoor | RE-6803 PU indoor | RE-3801 Silicon | RE-518 PU | RE-2120 Epoxy | |

| Weight Ratio | A: B | 100:105 | 1:4 | 10:1 | 1:1 | 5:1 |

| Viscosity Part A | Mpa.s | 900 | 100 | 2000 | 300 | 2000 |

| Viscosity Part B | Mpa.s | 500 | 1500 | 50 | 300 | 300 |

| Pot life | Min | 20 | 25 | 40 | 30 | 40 |

| Curing condition | @25℃ | 3~5h | 3~4h | 2~4h | 15h | 10h |

| @60℃ | 1~2h | 1h | – | 8h | 2h | |

| Cured Properties | ||||||

| Visual Colour | Clear | B/Y | B/W | Clear | Clear | |

| Hardness | (Shore A/D) | 75~85A | 75~85A | 20A | 55A | 70A |

| Service temperature | ℃ | -40~80 | -40~120 | -60~220 | -40~80 | -40~120 |

| Out door anti-yellow | Years | 3~5 | – | 3~5 | 2~3 | 3~5 |

| Water absorption | % | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| Flame retardant | UL94 | – | V2 | – | – | – |

Benefits&Features:

1.RE-4118 is a low-viscosity, easy-to-operate outdoor lighting strip potting adhesive, with strong adhesion to metal substrates, can adjust the light diffusion effect, adapt to high and low-temperature environments, and high waterproof performance, weather resistance can reach more than 5 years.

2.RE-6803 is a low viscosity, easy-to-operate indoor lighting potting adhesive, that can be operated manually or mechanically, in addition to good waterproof and shock resistance, flame retardant properties also meet UL 94 V2 grade, matte or glossy after curing customizable product performance at your choice.

3.RE-3801 Organic silicone materials have superior temperature resistance and can remain stable in environments up to 220° to protect products.

4. Flexible ratios, different hardness, flexibility, water resistance, Flame resistance, temperature, and weather resistance can be tailored to your requirements.

Application Guide:

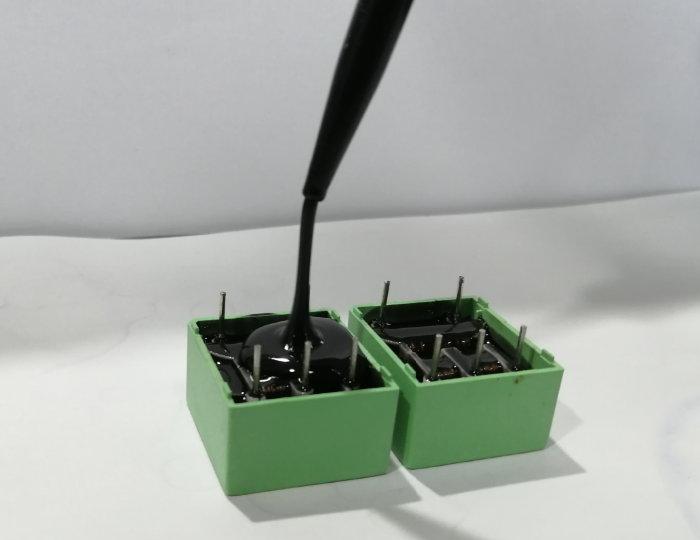

RESINOO new materials are used in Electronics potting, power encapsulation, mold filling, doming stickers, Led lights, handcrafts making, flooring and the insulation of other electronic components, moisture-proof, confidential encapsulation,anti-slip, and wear resistance, etc. It is the user’s responsibility to determine the chemical, mechanical, and thermal compatibility of substrates prior to using any of the suggested methods.

- Store at a temperature of 25℃ or cool and dry place. Avoid sunlight and high temperature or high humidity environment. Also, avoid storing it on the cold floor directly, Keep sealed away from light, and store it in a wooden container or on cardboard.

2. Use up as soon as possible when opened. It is strictly forbidden to expose to the air for a long time after it is opened to avoid affecting the quality of the products. The shelf life is 1 year at a room temperature of 25℃.

If the primary agent and curing agent are opened, they should be used up as soon as possible and if not, they should be stored immediately in a sealed container to avoid moisture.

◆Substrate preparation:

When Potting for electronics, many defects result from the presence of moisture, grease, oil, dirt, flux, and other board contaminants. Therefore, it is highly recommended that the user ensures the cleanliness and dryness of a surface prior to potting.

1. Wear disposable gloves and clean the surface with alcohol or any other degreasing solvent.

2. Let the surface dry completely. Elevated temperatures can accelerate drying.

◆Crystallization&Solidification:

Crystallization is the formation of solid crystals and is common in epoxy resins. Over time the crystals may settle, causing the material to be more dense or harder at the bottom of the container. They may appear as tiny particles or cloudiness in clear resins. This phenomenon does not indicate that the material is defective, and it is easy to reverse.

If crystallization occurs, reconstitute the product by warming it to between 55 and 65 °C until it becomes fully re-liquified. Let the material cool to room temperature before mixing to prevent flash cure.

When dealing with large production volumes, contact RESINOO Technical Support for assistance.

◆Mixing&Working:

Estimate the part A and B volumes that will be needed for your application prior to mixing. To avoid waste, the mix required epoxy amounts only when ready to operate. Ensure the material is used and applied within the working time. If the working time is exceeded, the material will begin to gel or harden.

See Pot life in the sheet or the product’s TDS for the appropriate mix ratios and working times of RESINOO epoxy potting compounds.

Manual operation is always subject to error unless you are a highly experienced expert, and if your goal to further improve your craft, it’s a good idea to consult our technical team to use automated equipment for dosing and dispensing to achieve savings in material usage, improved yields and high product performance.

Disclaimer: This information is believed to be accurate. It is intended for professional end-users who have the skills required to evaluate and use the data properly. Resintech(Shenzhen) New Material Co., Ltd. does not guarantee the accuracy of the data and assumes no liability in connection with damages incurred while using it.