PU crystal adhesive BZ-315

I. Characteristics

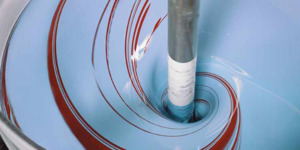

BZ-315A/B series is a two-component room temperature curing 100% solid polyurethane resin system, that does not contain any solvents, after curing to form a clear, transparent, crystal clear protective coating, widely used in signs, nameplates, and other crafts drip. BZ-315A/B has excellent weather resistance and UV resistance after curing, in the outdoor sunlight can ensure more than 3-4 years without changing The surface is smooth and transparent, which can enhance the texture of the products and win you the reputation of customers.

II. Description of product characteristics

BZ-315A is a polyisocyanate component, and BZ-315B is a polyol component, according to the requirements of different customers can provide different curing material hardness, different curing time, and different viscosity products, to meet the requirements of manual drip and mechanical drip.

Composition.

BZ-315A

1. alicyclic isocyanate R-N=C=O

2. Polyol resin R-[O-CH2-CH]nOH

BZ-315B

1. polyol resin R-[O-CH2-CH]nOH

2. alicyclic isocyanate R-N=C=O

3. Catalyst C8H8HgO2; CH3COOC6H5Hg

Color:

BZ-315A: colorless and transparent liquid

BZ-315B: colorless transparent or light yellow viscous liquid

Mixing ratio:

weight ratio A: B=1:1, (the ratio error is within 2%, and A agent as accurate as possible)

Viscosity value (25℃): BZ-315A: curing agent 570±200 mPa-s

BZ-315B: Main agent 360±200 mPa-s

After mixing: 390±200 mPa-s

Density (25℃): BZ-315A: 1.02±0.05 g/cm3

BZ-315B: 1.00±0.05g/cm3

Operating time (100g, 25ºC) 16±5min, recommended being used up within 16min.

Curing time: 25ºC, 7-9 hours, the curing time will be increased accordingly when the temperature decreases; if heating curing is required, the recommended temperature is 60 ºC and 1-2 hours to complete curing.

Shelf life: 3 months in a dry environment within the temperature range of 15 ºC to 25ºC in the original sealed drum.

Properties of the gel after mixing and curing Units or test conditions

| Appearance | Colorless, transparent, smooth surface, no ripples, | visual inspection |

| Hardness | 84±10 | Shore -A |

| Water absorption | ≤0.2% | after 30 days of immersion |

| Temperature resistance range | range -40℃~80℃ | |

| Weather resistance | 168 hours artificial climate aging test, No yellow color, no oil on the surface, no chalking | colloid Irradiation (340nm): 0.5w/m2;humidity: (60~80)%;Blackboard temperature: (65±2)℃;Rainfall cycle: 18min/102min(spraying time/no spraying time). |

III, the use of process profile

BZ-315 is divided into manual drip type and mechanical drip type, manual drip type can be used for a long time, slow curing, mechanical drip type can be used for a short time, curing fast.

1、Manual drip process

a、 Control the ambient temperature at 25℃, relative humidity <70%, BZ-315 may crystallize at low temperature, please heat at 60 degrees for 12 hours to recover to clarified liquid before use. In winter, the heating time should be extended as much as possible depending on the situation.

b、 Place the substrate on a horizontal surface and fix it with a sticker.

c、Clean the surface of the substrate from dust and oil.

d、 Weigh BZ-315A and BZ-315B correctly and mix well according to the weight ratio of 1:1.

e、Evacuate the mixture to remove the air bubbles.

f、Manually drip inject the surface of the substrate.

g、Poke the glue with a needle to make the glue spread all over the surface and remove the residual bubbles.

h、 7-9 hours to complete the curing can be closed container, when the temperature is low, curing time will be correspondingly long.

2. Mechanical drip process

Note: When the automatic glue dripping machine is to be cleaned, it can be cleaned by using acetyl acetate solvent.

a 、 Pour BZ-315A and BZ-315B into the automatic glue dripping machine A and B glue barrels respectively, and extract vacuum for 30 minutes.

b 、Insert the lifting pump and seal it respectively.

c 、Adjust the ratio of A.B material (100:100) with an electronic scale (precision 0.1G) and place the substrate on the horizontal surface and fix it with stickers.

d、Place the substrate on the horizontal surface and fix it with a self-adhesive.

e、Clean the dust and oil on the surface of the substrate.

f、Clean the pipe mixer and pour the head with ethyl acetate.

g、Punch the material and remove the air bubbles in the pipe, mixer, and pouring head.

Dripping on the surface of the substrate

h 、Paddle the glue with a needle to make the glue spread all over the surface and pick out the residual air bubbles. When the glue is drawn, put it into the oven at 55℃-60℃ and bake for 1 to 2 hours.

i 、When the temperature is low, the curing time will be longer.

IV the details of the operating instructions and precautions (manual use as an example to explain).

(a), the recommended operating environment.

Dry constant temperature clean workshop (recommended workshop operating temperature 20ºC ~ 25ºC), ventilation, workshop humidity to be controlled at 70% or less, indoor conditions fixed. Special attention should be paid to controlling humidity during the rainy season.

(II), the use of the preparation.

(a) deal with the substrate to be dripping glue (clean, dry, no impurities), if the LED substrate, it is recommended that the solder joints do washboard processing, so as not to flux residual ingredients and PU adhesive reaction. After the washboard treatment, we should pay attention to the washboard water evaporating and then wipe the washboard part with a dry rag.

(b) Prepare the glue pot or drip pot, stirrer, requirements: clean, dry, no impurities, do not use the glue pot or drip pot, stirrer with other glue before. This point should be noted.

(c) Weigh BZ-315A/B correctly, according to the weight ratio of 1:1. After dispensing the glue, please pay attention to putting the cap on the glue bottle and tightening it immediately to avoid the water gas in the air from entering the glue bottle.

(c) Stir well: Stir well in the same direction, and pay attention to stirring as much as possible to scrape the bottom and side walls, so that the stirring is more uniform; stirring time is controlled within 90 to 120 seconds (1 minute and a half to 2 minutes) is enough.

(d) Vacuuming.

Vacuum the agitated glue directly with the vacuum machine within 90 to 120 seconds (1 minute and a half to 2 minutes).

(e) Glue dripping.

Drip glue manually on the surface of the substrate, and poke the glue with a needle to spread the glue all over the surface, if there are residual bubbles, you can also use a needle to pick it out.

It is recommended to use the glue within 30 minutes to achieve the best results and improve production efficiency.

(F), curing.

Under the condition of room temperature 25ºC, about 7-9 hours of natural curing. When the temperature is low, the curing time will be correspondingly long. If you need to heat curing, the recommended temperature is 60 ºC, 1-2 hours to complete curing.

V PU glue use and storage precautions

(A), about the crystallization phenomenon at low temperature

BZ-315A may crystallize after being placed below 15ºC (referring to the average temperature of 24 hours) and greater than 24 hours and the crystallization phenomenon will disappear if the temperature rises.

In autumn or winter, A-glue can be recovered to clarified liquid at 60℃ for 12 hours, then taken it out and leave it for 30 to 50 minutes to cool slightly before use. (Note, the gum just produced doesn’t need to bake so long, but the time placed more than)

(B), about allergy

1. Manual operation of BZ-315 may cause allergies to some specific people, such as those who are allergic to chemicals.

2. It is best to wear film gloves during operation, and wash hands with soap and parts in contact with the glue immediately after operation.

3、The glue operation workshop should be properly ventilated, and the blower can be increased; the vacuum gas extracted by the vacuum pump should be discharged to the outdoors, not directly into the workshop environment.

4. It is forbidden to use for asthma patients.

(C), about glue preservation and use

1、Optimum condition: constant temperature and humidity, 25℃ is appropriate, and humidity is below 70% is appropriate.

2. Recommended environment: general workshop environment, closed and protected from light, can be stored for three months.

3. The glue should be used up within one month when it has been opened and used, and attention should be paid to covering the lid.

4. In the rainy season from March to May, the operation workshop should pay special attention to the humidity, if the humidity is more than 90%, it is recommended to dehumidify.

(D), glue curing

1. 25℃ constant temperature, 7-9 hours can be cured naturally.

2. temperature below 15 ℃, and the temperature difference between day and night, to 24 to 36 hours curing.

3. heating curing, 60 ℃ two hours or 70 ℃ an hour; the low temperature can be slightly extended heating time.

4. winter temperature is too low, the workshop can increase the heater to facilitate the shortening of curing time.

VI. Packaging specifications.

The package is 5KG, 20KG, 50KG, and 200KG metal drums.

VII storage and transportation and other considerations:

1. These products are non-dangerous products, transported as general chemicals.

2. Please store it under the condition of relative humidity <70% at 15℃-25℃, avoiding light and honey closed, the storage period of the product is shown in the packing barrel.

For manual drip injection, please weigh correctly according to the ratio and stir well, weighing more than 100G, the use time will be shortened.

3. If the material comes into contact with the eyes, immediately open the eyelids and flush with plenty of water for more than 15 minutes.

4. When the material comes into contact with the skin, wipe it off with a cloth and then rinse the affected area with water and soap.

*Note: The above performance data are typical data of the product tested at 70% humidity and 25℃, and are for customers’ reference only, and cannot guarantee all the data that can be achieved in a specific environment. Please refer to the actual measurement data when using the product.

- Melap Portugal — guia de casinos online licenciados e também sites para apostas dentro de território português

- International Dating Challenges: How to SolveThem

- Znaki Sverige: nyheter om de verksamheter som påverkar den moderna världsbilden

- Best Pills for Erection: Your Comprehensive Guide to Enhanced Performance

- TOP 6 Epoxy Resin Applications in 3C Electronics Industry