Perhaps you have come across any epoxy resin project . Do you wish to know how to use Chinese epoxy?, how long Chines epoxy lasts?, where to buy Chinese epoxy? Is epoxy resin waterproof? Don’t you worry. You are reading a perfect article about Epoxy and the Chinese Epoxy industry.

What Are the 3 Types of Resin?

Chinese industry produces the following types of resin

Epoxy

Polyester

Vinyl Ester

The Chinese Market for Epoxy Resin

Over the past decade, Epoxy Resin consumption in China has skyrocketed. We can expect a similar increase in output and demand over the coming decade. The rising industrial output, imports and exports, and consumer spending bolsters China’s economy . We are among the top producers of resin hardener in the world.

Epoxy Resin, What Is It Used For?

We take two distinct substances, epoxy and hardener, to create the mixed epoxy resin. After combining the two, a chemical reaction occurs, and the resin hardens. As a multipurpose substance, epoxy resin has many applications.

It’s ideal for various uses thanks to its strength and longevity. If you are searching for a substance that is scratch resistant, RESINOO is a great option to go for.

Epoxy adhesives are now available at most hardware stores in China. The applications of epoxy are growing. New varieties of the material are now created to suit specific fields and products in a better way. Epoxy resins are used in a variety of applications, including:

· A variety of adhesives for various uses

· Used as a binding agent in concrete and mortar

· Solid foams

· Skid-resistant paints

· Cementing sand-covered oil fields

· Fabrication of industrial coatings

· Materials for potting and enclosing

· Polymers bonded with fibers

Epoxy is used as the resin matrix in fiber-reinforced polymers. It can be used in plastics since it does an excellent job of keeping the fiber in place. Fiberglass, carbon fiber, aramid, and basalt can reinforce a structure with epoxy resin.

Is Epoxy Resin Permanent?

You may wish to know whether epoxy resin is temporary or permanent? Or how long does it last? Chinese Epoxy resin lasts for several years. It is usually reinforced with an hardener to make it lasts longer. We cannot say it is permanent but it takes over 10 years long before losing grip.

How long epoxy resin lasts?

When epoxy resin and hardener are kept in airtight containers at room temperature. Such storage extends shelf life by years. Polyester resins has a short shelf life of six months before it becomes a useless jelly.

How Does Epoxy Resin undergo a Transformation?

Epoxy resin and hardener react when mixed, changing the liquid’s state to solid. Cure time refers to how long a substance undergoes a chemical change from a liquid to a solid state. Epoxy goes through a series of transformations while it cures, starting as a liquid and ending as a solid.

The Membrane of Reinforced Epoxy Resin

Glass fiber-reinforced epoxy resin can make a membrane of 4mm. thermosetting material. The components of epoxy resin are dosed and mixed as directed. Alternating layers of resin and glass fiber are installed following the manufacturer’s instructions.

The epoxy resin is used to prime the surface of the substrate after cleaning and prepping. It is then used to fill any residual holes or fractures in the concrete.

Epoxy Brands Available in China

We provide different epoxy resins here in China. You can access them online or visit our physical stores. If you choose to buy online, kindly check the reviews from other previous customers.

Some of the brands available

· Total Boat

· RESINOO

· Aqua seal

· Loctite

· Gorilla

· JDisction

Is epoxy resin waterproof?

Yes, Epoxy resin has a remarkable property of sealing. It forms a waterproof (and anti-corrosive) layer of protection.

Is epoxy resin unbreakable?

Yes, hardened epoxy resin is like a plastic material hence can break when it hits a hard surface.

Does Epoxy Yellow Over Time?

Yes, after some time, epoxy hardener becomes yellow as a result of oxidation. This process kicks off the moment the hardener’s container is opened and air is allowed to enter,but it’s very slow process,It takes years to see the changes with the naked eye. The rate disco occurs to varying degrees. It depends on how long air enters the bottle to the substance. Exposure to ultraviolet radiation make epoxy resin yellow faster.

How I Prevent Epoxy From Turning Yellow?

Epoxy resin discoloration can be avoided during the product selection phase. UV stabilizers can stop resin from becoming dull. Also, it prevents delamination, cracking, or chalking when exposed to sunlight. Nonetheless, UV stabilizers can delay the inevitable fading. They aren’t able to put a stop to it permanently.

Why Did My Epoxy Turn Green?

Green color is from reaction between oxygen molecules and secondary amine groups.

How Do You Know When Epoxy Is Fully Cured?

When the epoxy completely cured, it will be hard to the touch and will no longer be sticky. After 24 hours, epoxy is cured,do not touch them short after applied.

Yet, you can hasten the curing process by placing the epoxy in a warm oven or under a heat lamp,it can cured as fast as in 30minuts at a temperature of 60℃ or above. Epoxy curing can be verified with the help of a moisture meter.

How Many Coats of Epoxy Do I Need?

Two to four is the typical number of layers of epoxy needed for a project. Make sure you

Recoat at the appropriate time

Recoat in the appropriate manner

The surface should be adequately prepared for as many coats as you intend to apply.

What Happens if Epoxy Gets Wet?

The resin starts to soften at around 35 degrees Celsius, so that could pose problems if it gets moist. Wet resin does not get along well with other chemicals. You can void using it in any sealed areas where acids might come in contact with it.

After the epoxy has hardened, it’s likely that certain areas will remain damp or pliable. Soft areas are formed when resin is not mixed properly. Hence, unmixed material sticks to the sidewalls.

Why Is My Resin Bendy After a Week?

Limited cure time. The resin probably needs more time to set, and this is why it is bending. Give your epoxy resin enough time to cure.

Will Epoxy Dry Without Hardener?

It is almost impossible for epoxy to dry/cure without hardener. The chemical reaction only occurs when they are combined with an epoxy hardener. Without the hardener, the resin would stay as a permanent liquid. When put to a floor and would never turn into a hardy flooring system.

Can You Layer Epoxy Without Sanding?

To achieve a strong binding between resin layers, sanding is required. The two layers may come apart in time if you don’t sand them. If you sand the epoxy glue between coats, you can not only remove the flaw but also add some bite to the layer below it.

Do You Need to Sand Before Epoxy?

It is good to sand smooth non-porous surfaces and fully abrade them before applying epoxy. Using eighty-grit aluminum oxide paper will provide the epoxy a nice surface texture. Keying is thus easy. The bonding surface should be firm. Before sanding, scrape away any peeling, flaking, chalking, blistering, or old covering.

Can You Put Epoxy Over Epoxy Without Sanding?

No, you cannot put epoxy over epoxy without sanding. Since the epoxy has hardened, a chemical bond is no longer an option, so a mechanical bond must be used instead. It implies that the before applied coat needs to be softly sanded before the next one is applied.

Epoxy and UV Resin, Key Differences

UV resin cures only when exposed to ultraviolet light. But, epoxy resin doesn’t need extra curing time or help. It can have layers up to 1 mm thick. A layer of epoxy resin can be up to 5 centimeters thick in a single casting.

When compared to UV resin, the longevity of epoxy resin is superior. Epoxy resin is resilient to heat and scratches. UV resins are brittle and easily scratched. Resin is an organic material secreted by some plants. It is sticky, flammable, and insoluble in water. Epoxy resin and ultraviolet (UV) resin are two of the most prevalent resin compounds.

Can Epoxy Resin Be Used on Glass?

Yes, provided the glass surface is clean, epoxy resin will adhere stick to it. It is important to clean glass surfaces before applying resin. Resin can thus adhere properly. Because resin can adhere to practically any surface, you can’t use a glass baking dish as a mold.

Can You Polish Resin With Toothpaste?

Yes, It’s simple to polish resin with toothpaste by hand. A toothbrush, some toothpaste, and some water are all you need. Start by applying water to the resin’s surface. Secondly, coat your toothbrush in toothpaste. Use the toothbrush to buff the resin until it shines.

What does epoxy resin not stick to?

Epoxy does not stick to the following materials:

Hot glue

Plastic

Silicone

Polythene bags

Tuck tapes.

Such further properties make epoxy resin widely useful for domestic repairs.

Benefits Associated With Epoxy Resins

Different cheap epoxies are food-safe. Different tests have been done to confirm the food-safe epoxy. Heat resistance of Chinese epoxy makes it useful in any ambient temperature. The non-toxic nature of epoxy resin makes it ideal for coating plastic materials. The materials can be used for food and drink storage. Epoxy resins are commonly used to prevent silicone

To meet a shiny finish, simply mix different resins are mixed with mica powder. Chinese epoxy resin is useful globally today. Basically, china made products can be easily repaired by epoxy resin. The different properties of epoxy resin makes it useful in some domestic ways.

Is Liquid Glass the Same as Epoxy?

Paint, acrylic paint, and oil-based paint are not advised for use with epoxy. Liquid Glass is the best epoxy for dispersing color and suspending inks and powders. So yes, liquid glass is the same as epoxy.

Common Repairs Using Epoxy Resins

As a two-component glue, epoxy resin is frequently used in repairs. It’s a common ingredient in sealants and adhesives and can be used to mend broken items. After being combined, the adhesive will set and provide a secure hold. You should use epoxy resin to fix fragile objects like:

Vases

Sculptures

Ornaments

Epoxy resin can be used as an adhesive for many fixes. It forms a strong bond fast after application and is simple to work with. Epoxy resin is an excellent material for fixing broken items and making sealants.

How Do You Apply Epoxy Resin?

Epoxy resin is most commonly known for its excellent bonding properties. It can also give your item a shiny finish, sometimes giving the impression of water or glass. Follow these simple steps to apply epoxy resin

Before You Start Using

You just need to take a few elementary safety measures for everything to go smoothly. When working with epoxy resin, always wear protective gear, such as latex gloves. Because of how quickly epoxy can dry, you should only mix as much resin and hardener as you will use. Mix within ten minutes. It ensures the substance keeps its intended viscosity and may still penetrate effectively.

Choose Proper Materials To Use

When applying an epoxy substance, foam roller brushes are the most effective tools. One reason for this is that bristle brushes don’t always provide a perfectly even coat.

The Actual Application of Epoxy Resin

Begin by rolling on a thin layer of activated resin with the foam roller. Don’t try to cover too much ground with short, choppy strokes, but do stick to your long ones. To achieve the desired results, the coating ought to be homogeneous in:

Thickness

Appearance

As you plan to smooth out the surface between coats of paint, a few small imperfections in the base coat are okay.

The Best Epoxy Resin for River Tables

Epoxy resin is a flexible material that may be applied to various tasks. Epoxy resin will likely be used in the upcoming project to create river tables. River set epoxy resin is a deep-pour resin. It has a water-clear finish and may be poured up to five centimeters deep in a single pour. Due to this, it is the best option for jobs that call for a deep, water-clear finish.

High water and moisture resistance is another property of river set epoxy resin. This makes it the ideal option for projects that will be in contact with dampness and water. A comparable substance explicitly used in woodwork is called timber set epoxy resin.

One of the key advantages of using it for a river table is that epoxy resin is a deep-pour resin. It indicates that the resin may be poured, producing a water-clear finish. Thus, there is no need to be concerned about unsightly blemishes or scrapes.

How Do You Mix Liquid Glass Epoxy?

You can mix liquid glass epoxy by combining two volumes of base resin with one volumes of curing agent.

Place all ingredients in a large mixing bucket

Stir by hand for a least of six minutes.

Stirring for six to ten minutes makes it thoroughly mixed together.

- Use automatic metering dispensing equipment

Why Is My Resin Still Soft After 24 Hours?

The resin probably needs extra time to cure. That is the reason is why you’re having problems with bending resin. The solidity of ArtResin can be expected to reach 95% after 24 hours. Before the resin has set for 24 hours, it may be shaped or moved, but doing so may cause it to bend.

Is There a Cheaper Alternative to Epoxy Resin?

Yes, polyester and vinylester are cheaper than epoxy resin. The two are frequently used for repairs and structures on fiberglass boats.

What are Casting Resins?

A low-viscosity epoxy resin called casting resin has two primary parts:

The solid resin

A complementary hardener.

Casting epoxy resin, also known as deep pour resin, is utilized for thick pours up to 2 inches in thickness. It is frequently used for jewelry, embedding and encasing items, and other things. For wet sanding of polyester resin, we use ordinary sandpaper.

Here are the eight best casting resins in the market today:

· RESINOO resins

· ICE Epoxy resins

· Envirotex Jewelry Epoxy resin

· The expert Epoxy resins

· J-Diction Epoxy resin

· Glass Cast 50 Clear Epoxy resin

· Alumilite Amazing Clear Cast Epoxy resin

· Pourable Plastic Clear casting resins

How will cold weather influence epoxy resins?

Slower curing, more air bubbles, and a cloudier finish. Low temperatures prevent it from fully hardening, leaving it sticky. Use epoxy resins at 24 degrees Celsius. Warm up the resin and hardener in a warm water bath. Warm it when the temperature is substantially lower than 26 degrees Celsius.

Any side effects of epoxy Resin?

The common reactions to prolonged exposure to epoxy resin include:

Rashes

Itchy eyes

Stuffy nose

Sore throat;

Also, some people develop asthma or skin allergies. Headaches and dizziness are just some of the side effects. They may result from the solvent additives. Chemicals used in epoxy resin systems emit irritating vapors or spray mists. The sprays can cause respiratory irritation.

Why You Should Think of Purchasing Epoxy Resin from China

Some of the factors that can make you think of purchasing Chinese epoxy are:

The increasing ecological and social awareness

The rapid depletion of petroleum resources

The implementation of new environmental policies

Such factors have contributed to developing novel composites and environmentally friendly, green materials. Chinese epoxy has the answer.

Why by Epoxy Resin From China?

Fiber optoelectronics and dentistry use polymers that harden when exposed to ultraviolet light. Chine epoxy resins will help you in:

Lamination

Casting

Fixture

Mold applications in the industrial tooling industry.

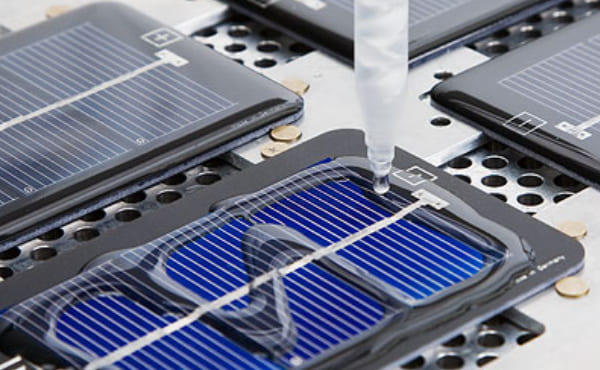

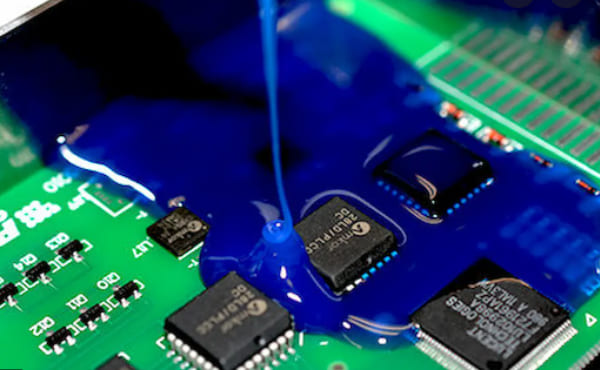

Chinese Epoxy resins have several applications in the electronics industry. They include

Insulators

Transformers

Generators

Switchgear fabrication.

- water meter encapsulation

- LED light protection

- Wall stickers potting

Epoxy resin is helpful around the house for fixing broken:

Ceramics

Glassware

Furniture

Metal and leather.

After it has fully hardened, the link is compelling and long-lasting. Epoxy resins have a place in maritime repair, but they shouldn’t be utilized on a boat’s exterior. Prolonged exposure to sunlight can break down the resin. Epoxy resin has utility as a material for other creative endeavors as well.

What Are the Current Prices of Epoxy Resin in China?

Our brands come at different prices based on quality and quantity. For good quality, the price is relatively higher compared to lower quantities. To cater to the needs of different consumers, we stock different quantities as well.

Is Epoxy Resin Expensive?

Epoxy resin, like other art and craft supplies, may be quite expensive. It depends on the variety and quality you opt for. Pricing for epoxy ranges from $510 to $130 per liter. With mass production of Epoxy resin in China, our prices are relatively low. Compared to other nations, our prices are friendlier.

Where to Buy Epoxy in China

Here in China, we sell epoxy in larger quantities, perhaps more than you think. We sell bulk quantities of the fully range epoxy. While if you are engineer and would like to customiz the formulation of a particular resin, RESINOO are available to provide samples in 3 days.

Key Takeaways.

You’ll most likely find it in epoxy paint for your pool or garage floor. Epoxy resins resist electricity, mechanical stress, and high temperatures. In coating consider the maximum thickness you can apply. Not all volatile organic compounds behave the same. You can buy the brand that best suits you.

In 2021, as global supplies were running low. China saw a significant increase in the volume of epoxy resin it exported. From the beginning of the year to the middle of the year in 2021, China saw an increase in epoxy resin exports. The exports were of around 118.0%. Will an increase in exports help to absorb any extra Chinese output? Some improvement is possible. Besides, it won’t be enough. Export volumes have been dropping for months as global supply has eased.

Mass production will keep our prices low. Amidst the global shortage, we plan to keep our supply steady.